COIL PACKING LINE SAFETY GUIDELINES

Training and Checks

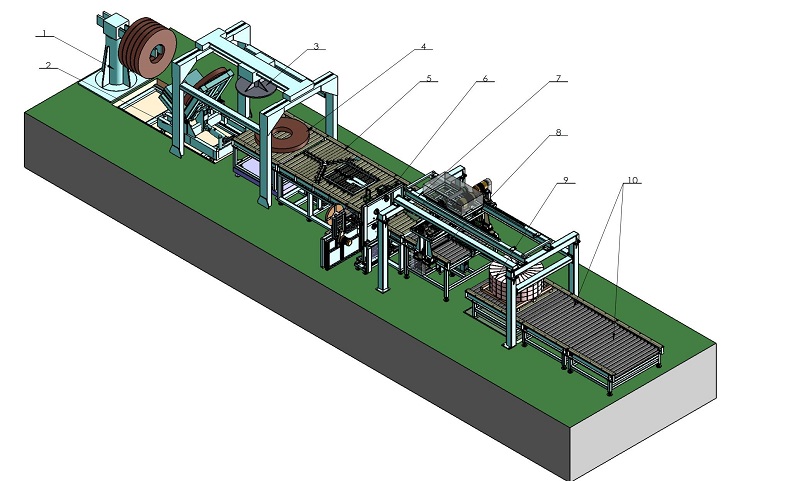

- Training: Train all operators on each machine: downender, turnstile, wrapper, stacker, and strapper.

- Checks: Inspect all machines before use.

- Safety Zones: Set up clear zones around each station.

Loading and Operating

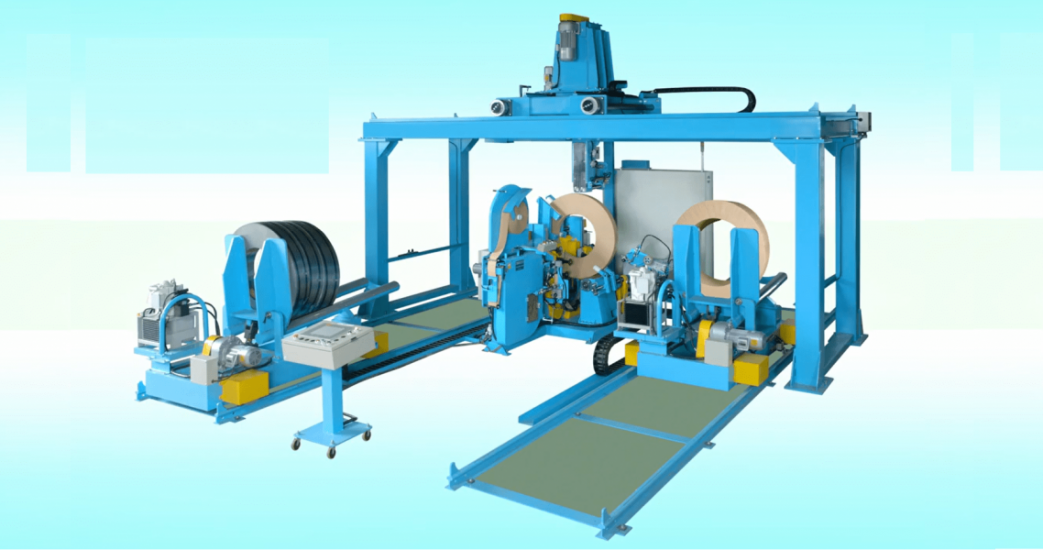

- Downender: Check the sensor and hydraulic station before coil loading.

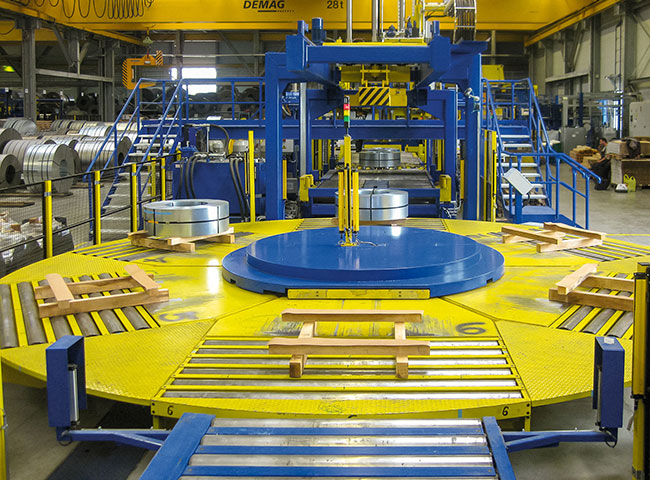

- Turnstile: Properly position and secure coils with crane loading.

- Lifting: Use correct equipment and follow load limits.

Safety During Use

- Distance: Stay clear of machines while operating.

- No Adjustments: Don’t tweak settings when machines are running.

- Emergencies: Know where all stop buttons are.

Unloading

- Wait: Don’t approach until machines fully stop.

- Check Stability: Make sure coils are stable after wrapping.

- Cleanup: Remove debris after each unloading.

Maintenance and Emergencies

- Maintenance: Regularly maintain all stations.

- Emergency Drills: Practice and update emergency plans.

- Report Incidents: Report and investigate all issues promptly and backup the log from HMI.

Request A Price Quote Download PDF

![[field:title/]](/source/images/shjl-logo.png)

Steel coil loading systems are designed to join the slitting line with ender, crane, and forklift operators. The strapping system takes care of the coil while wrapping and protecting it in accordance with your choices. Our system helps you obtain significant cost savings by adapting efficiently to your needs. We have a solution for you to have a quick ROI — let us know if you’re interested on this topic. Coal loading systems are designed to join the coal sorting line with ender, crane, and forklift operators. This system allows strapping machine to take care and pile up the coal according to your preference. Our system helps you save a lot of time and money by adapting to your needs effectively. We have an ideal solution for you if you are looking forward to getting instantaneous results. Our company is specialized in industrial automation, such as servo motor products, electric actuator, linear motion guide rail and various types of inkjet printer consumables and we also do provide service all over China. We have experienced employees in this field so they can assist customers freely all over China and worldwide. If you are willing to buy or try any of them, please do not hesitate to contact us via our website or Alibaba website. We would be glad to assist you at any time.

Steel coil loading systems are designed to join the slitting line with ender, crane, and forklift operators. The strapping system takes care of the coil while wrapping and protecting it in accordance with your choices. Our system helps you obtain significant cost savings by adapting efficiently to your needs. We have a solution for you to have a quick ROI — let us know if you’re interested on this topic. Coal loading systems are designed to join the coal sorting line with ender, crane, and forklift operators. This system allows strapping machine to take care and pile up the coal according to your preference. Our system helps you save a lot of time and money by adapting to your needs effectively. We have an ideal solution for you if you are looking forward to getting instantaneous results. Our company is specialized in industrial automation, such as servo motor products, electric actuator, linear motion guide rail and various types of inkjet printer consumables and we also do provide service all over China. We have experienced employees in this field so they can assist customers freely all over China and worldwide. If you are willing to buy or try any of them, please do not hesitate to contact us via our website or Alibaba website. We would be glad to assist you at any time.