How Can I Ensure Cleanliness of Pallets in Food and Pharmaceutical Industries?

Keeping pallets scrupulously clean is paramount in sectors dealing with food and pharmaceuticals, where the stakes for sanitation are incredibly high. Despite the critical importance, the complexity of maintaining spotless pallets can be underestimated. Let's dive into practical methods and insights for safeguarding your supply chain with clean equipment.

Why Are Plastic Pallets Better Than Wood?

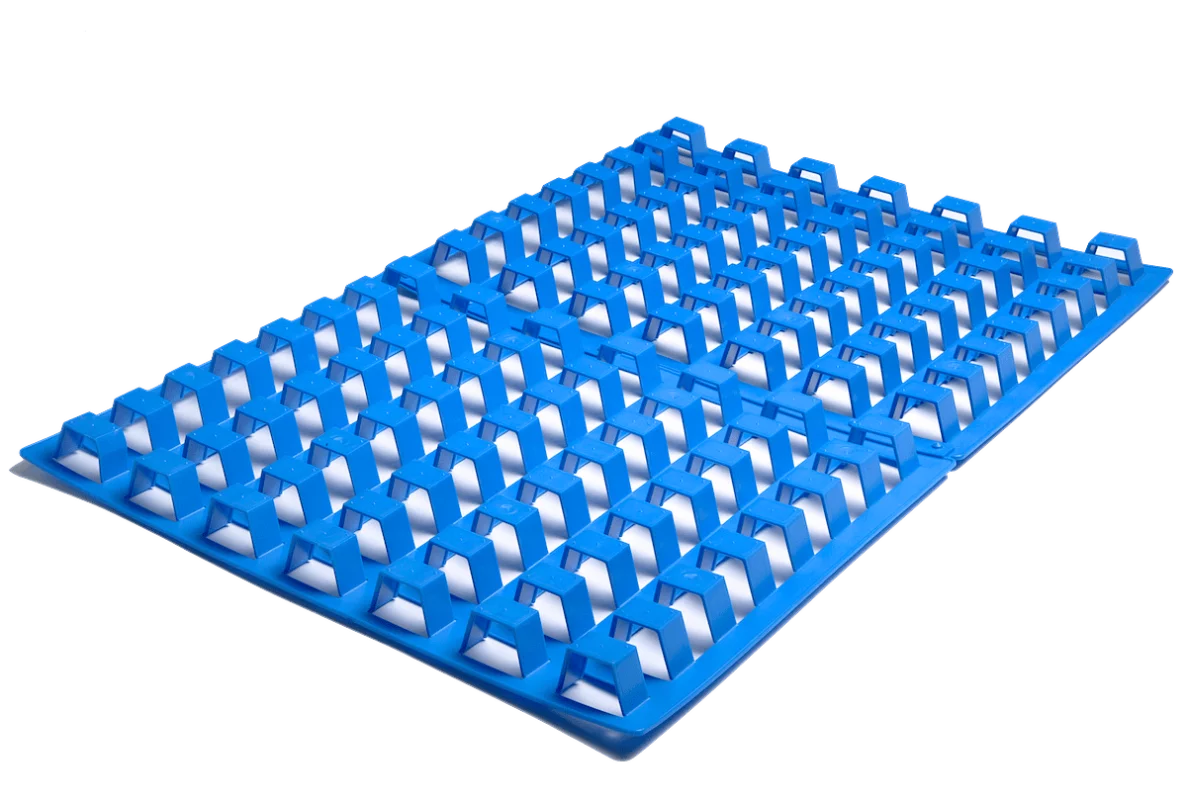

Plastic pallets offer remarkable benefits, particularly in terms of sanitation. Unlike wood, which is rife with tiny pores that trap bacteria and dirt, plastic pallets feature a smooth, non-porous surface that can be easily sanitized. This characteristic not only reduces contamination risks but also mitigates the transfer of unwelcome substances during shipment handling.

What Makes Plastic Pallets Stand Out?

-

Safety First: Molded as single units, plastic pallets eliminate risks posed by nails or adhesives in wooden counterparts. This structural advantage lessens chances of injury or product damage in the workplace.

-

Featherweight Durability: With designs that optimize both weight and strength, plastic pallets accommodate hefty loads while remaining easy to maneuver. Nestable types offer logistical benefits by maximizing storage space.

-

Weather Resistance: Capable of withstanding adverse conditions, plastic outperforms wood, which may degrade when exposed to moisture. No risk of cracking or rotting makes them enduring favorites.

-

Naturally Clean: Being inherently washable positions plastic pallets as an excellent choice for maintaining cleanliness, contributing to a hygienic environment in industries where sanitation is non-negotiable.

How Do You Maintain Plastic Pallets?

What Are the Risks of Neglecting Pallet Hygiene?

Failure to maintain clean pallets can lead to contamination and compromise the integrity of shipments, potentially causing significant financial loss and damaging reputations. Proper cleaning is essential to uphold safety standards and meet regulatory requirements.

How Should Plastic Pallets Be Cleaned?

While these pallets are easier to clean than wood, high standards must still be maintained. The method you choose will largely depend on the type and intensity of dirt or contaminants in question. Here's a look at some effective cleaning strategies:

-

High-Pressure Washing: For grime that won't relent, a high-pressure washer becomes indispensable. It's a robust method capable of clearing stubborn debris without harming the integrity of the pallet.

-

Power-Washing: This offers speed and efficiency, sanitizing hundreds of pallets in a short period. Using a drying feature accelerates the process without compromising results, making it ideal for keeping operations swift and efficient.

-

Manual Washing: Although more labor-intensive, this method allows close attention to detail. It's a viable option where budget constraints are a concern, albeit less efficient than automated solutions.

Are Automated Washers Worth the Investment?

The distinction between manual and automated options hinges on efficiency, scale, and regulatory adherence. While manual cleaning can suffice for smaller operations, automated washers promise thorough consistency, aiding compliance with stringent industry guidelines.

Why Opt for Automated Pallet Washing?

- Precision and Consistency: Machines execute repetitive tasks with refined accuracy, ensuring consistent results every time.

- Safety and Speed: Automation minimizes human error and reduces risks associated with manual labor, contributing to a safer work environment.

How to Properly Sanitize Plastic Pallets?

The process extends beyond simple cleaning; true sanitation targets microscopic threats like bacteria. The utilization of heat—whether through steaming or hot water—is preferred for its ability to obliterate resilient germs, fortifying sanitization efforts.

What Steps Enhance Sanitation?

Establishing a separate, clean space for washing prevents recontamination, allowing pallets to dry thoroughly and ensuring they remain pristine until their next use.

Discover Alternative Solutions

While plastic pallets are a dominant choice thanks to their myriad advantages in hygiene-sensitive settings, alternative offerings may also pique your interest. Diverse options such as metal or composite materials each have unique traits and can cater to specific operational needs.

In conclusion, maintaining the highest standards of cleanliness for pallets, especially in food and pharmaceutical industries, is non-negotiable. Regular sanitization, efficient cleaning procedures, and investing in the right equipment can protect not only your products but also your and clients' trust in your business. As we navigate through challenges of industrial logistics, adapting and utilizing innovative solutions become guiding principles for sustaining success.