How Do Stainless Steel Revolutionize Material Handling?

In the modern era of automation, efficiency in material handling is pivotal. One innovation that has elevated this domain is the stainless steel PalletPal, a spring-actuated, self-leveling pallet leveler. With over three decades of experience, I can attest to the transformative impact of such equipment in specialized applications. But what sets the stainless steel apart from others? Let’s explore its unique features, applications, and benefits in depth.

Why Choose Stainless Steel Construction?

The decision to use stainless steel in our construction is not arbitrary. It provides extraordinary corrosion resistance, which is vital in environments that are prone to moisture or chemicals. In my experience, this material choice substantially extends the lifespan of the palletizer, ensuring consistent performance over time. This durable build not only offers longevity but also makes the PalletPal suitable for a wider array of industrial environments where cleanliness and resilience are non-negotiable.

How Does Self-Leveling Improve Ergonomics?

One of the standout features is its self-leveling capability. Through a clever spring mechanism, it adjusts the height of the load automatically as items are added or removed. This innovation significantly enhances ergonomics, reducing the physical strain on workers by eliminating the need to constantly bend or stretch. During my career, I've seen firsthand how such advancements in ergonomics can lead to improved productivity and reduce workplace injuries.

What Makes the Easily Relocatable?

The inclusion of fork pockets is a game-changer in material handling dynamics. These pockets allow the PalletPal to be effortlessly moved using forklifts, facilitating flexibility in warehouse and production floor layouts. This feature ensures that businesses can dynamically adapt to changes in production lines without significant downtime, a vital consideration in fast-paced industrial settings.

Which Customizeable Options Enhance Functionality?

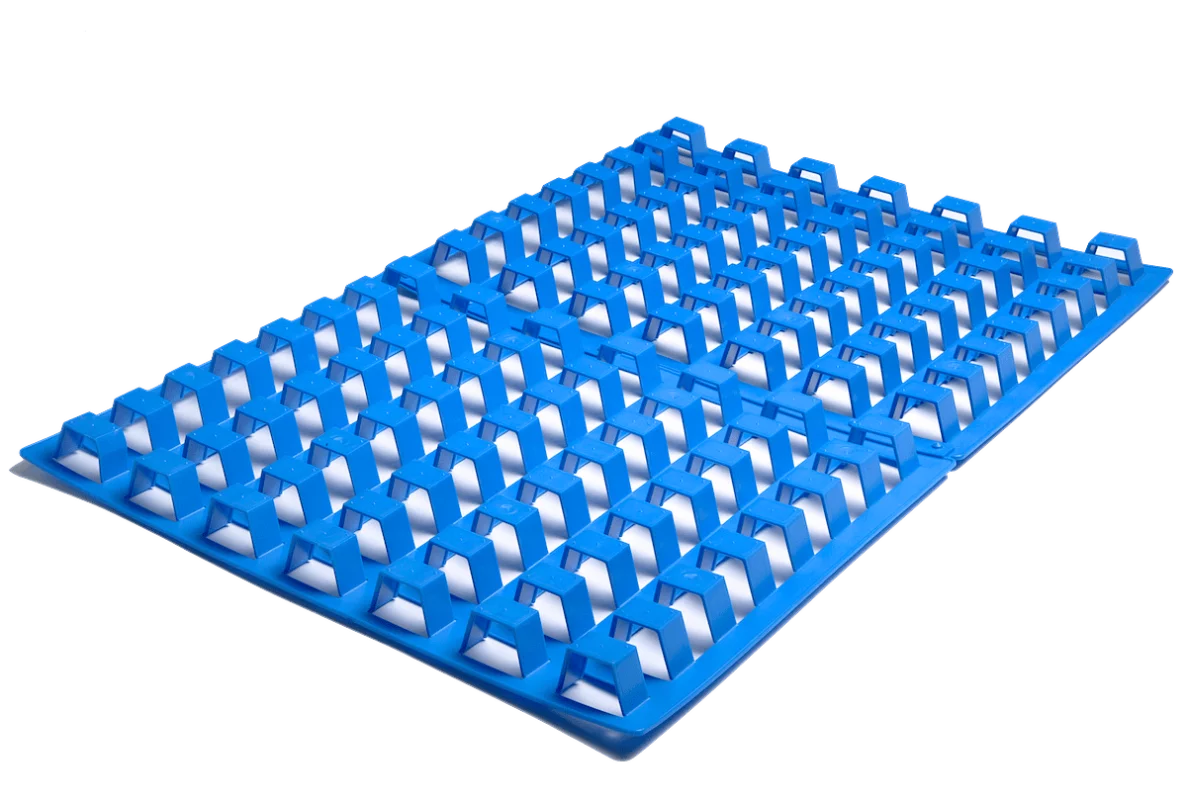

It doesn't come as a one-size-fits-all solution. Various customization options enhance its adaptability to specific needs. Consider the following:

- Phenolic Cover: Shields from debris accumulation.

- Solid Disc Cover: Ideal for non-standard pallets.

- Fork Pocket Caster Kit: Adds mobility with a floor lock.

- Leveling Feet: Compensate for uneven flooring.

- Bellows Accordion Skirting: Keeps areas underneath debris-free.

Each of these options can tailor to the unique challenges of different environments, providing businesses with the flexibility to modify their equipment as requirements evolve.

Can Additional Features Minimize Maintenance Needs?

The PalletPal's design is centered around minimal maintenance. With a built-in dampener to prevent overshoot and bounce during operations, the need for frequent servicing is remarkably reduced. In my practice, I've observed that minimizing maintenance not only cuts costs but also ensures the equipment remains operationally efficient for longer periods.

How Do Other Projects Compare?

While the stainless steel offers a robust solution, it's worth noting similar equipment in the industry. Products can bring unique features like rotatable platforms and customizable finishes. Meanwhile, the Low-Profile Levelers and Automated Turntables cater to specific material handling needs. Each possesses distinct attributes but shares a common goal—enhancing efficiency and safety in material handling.

In the end, selecting the right equipment requires a thorough understanding of specific operational needs and conditions. With technological advancements and a clear view of ergonomic benefits, businesses can significantly elevate their material handling processes. Whether it's through adjusting load heights automatically or ensuring durable performance in harsh environments, the benefits are tangible.

In conclusion, the stainless steel is a testament to innovation in material handling, offering ergonomic superiority, easy relocatability, and minimized maintenance. Its features are not just about meeting current demands but anticipating future needs. For those in the industry aiming to optimize their production lines, such equipment could very well be the key to unlocking next-level efficiency and safety.