In today's rapidly evolving manufacturing landscape, automatic steel coil packing lines have become integral to efficient production processes. However, even the most sophisticated systems can encounter challenges that impact productivity and output quality. Let's dive into a comprehensive analysis of common issues and their cutting-edge automated solutions.

Understanding Automatic Steel Coil Packing Systems

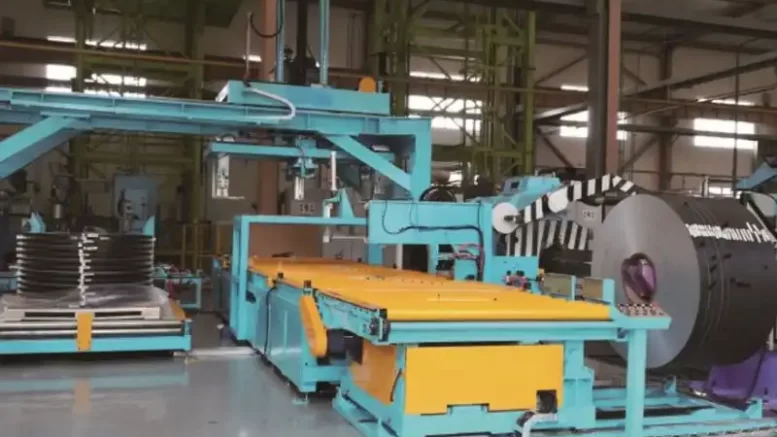

Before we delve into specific problems and solutions, it's crucial to understand what makes up a modern steel coil packing line. These advanced systems typically consist of:

- Conveyor systems for coil transportation

- Wrapping mechanisms for protective packaging

- Strapping units for secure bundling

- Control systems for automation management

- Sensing equipment for quality control

Each component plays a vital role in ensuring smooth operation and optimal packaging results.

Issue #1: Inconsistent Wrapping Tension

The Challenge

One of the most prevalent issues in steel coil packing is inconsistent wrapping tension. This problem can lead to:

- Loose packaging that fails to protect the coil

- Over-tightened wrapping that damages the material

- Uneven protection against environmental factors

- Increased risk during transportation

Automated Solution

Modern systems now incorporate intelligent tension control systems that:

- Continuously monitor wrapping pressure

- Automatically adjust tension based on coil specifications

- Provide real-time feedback to operators

- Store optimal settings for different coil types

Issue #2: Misalignment During Packaging

The Challenge

Coil misalignment during the packaging process can result in:

- Improper wrapper application

- Damaged packaging materials

- Increased production downtime

- Quality control failures

Automated Solution

Advanced alignment systems featuring:

- Laser guidance technology

- Computer vision systems

- Automated positioning mechanisms

- Real-time adjustment capabilities

These solutions ensure precise positioning throughout the packaging process.

Issue #3: Material Waste and Inefficiency

The Challenge

Excessive material waste in steel coil packaging operations often stems from:

- Improper material calculations

- Inefficient cutting systems

- Poor coordination between different packaging stages

- Lack of optimization in material usage

Automated Solution

Smart material management systems now offer:

- Precise calculation of required packaging materials

- Automated cutting with minimal waste

- Optimization algorithms for material usage

- Real-time inventory tracking and management

Issue #4: Speed and Throughput Limitations

The Challenge

Traditional packing lines often struggle with:

- Bottlenecks in production flow

- Slow transition between different coil sizes

- Manual intervention requirements

- Limited processing capacity

Automated Solution

Modern automated solutions include:

- High-speed servo drives for improved performance

- Dynamic speed adjustment capabilities

- Automated size recognition and adjustment

- Parallel processing capabilities where applicable

Issue #5: Quality Control Inconsistencies

The Challenge

Quality control issues frequently involve:

- Inconsistent packaging standards

- Difficulty in detecting defects

- Variable protection levels

- Limited documentation and traceability

Automated Solution

Advanced quality control systems featuring:

- AI-powered inspection systems

- Automated quality verification

- Digital documentation and reporting

- Real-time monitoring and adjustment

Implementation Strategies for Automated Solutions

Planning and Assessment Phase

The successful implementation of automated solutions requires careful planning:

- Initial Assessment

- Current system performance evaluation

- Production bottleneck identification

- Resource utilization analysis

- ROI calculation for proposed solutions

- Technical Requirements

- System compatibility checks

- Infrastructure requirements

- Integration points with existing systems

- Network and data management needs

Staff Training and Adaptation

A critical component of successful automation implementation is comprehensive training:

- Operator Training Programs

- Technical operation procedures

- Troubleshooting protocols

- Safety guidelines

- Maintenance schedules

- Management Training

- Performance monitoring

- Data analysis

- Resource optimization

- Quality control oversight

Cost Considerations and ROI Analysis

Initial Investment Breakdown

Understanding the financial implications of automation:

- Hardware Costs

- Equipment procurement

- Installation expenses

- Auxiliary systems

- Spare parts inventory

- Software and Integration

- Control system licenses

- Custom programming

- Integration services

- Testing and validation

Long-term Financial Benefits

- Direct Cost Savings

- Reduced labor costs

- Lower material waste

- Decreased maintenance expenses

- Improved energy efficiency

- Indirect Benefits

- Higher product quality

- Increased customer satisfaction

- Enhanced market competitiveness

- Better workplace safety

Future Trends in Steel Coil Packing Automation

Emerging Technologies

The future of steel coil packing is being shaped by:

- AI and Machine Learning

- Predictive maintenance

- Adaptive process optimization

- Quality prediction models

- Automated decision-making

- IoT Integration

- Real-time monitoring

- Remote operation capabilities

- Predictive analytics

- Connected supply chain management

Sustainability Innovations

Modern systems are increasingly focusing on:

- Energy Efficiency

- Smart power management

- Regenerative braking systems

- Optimal resource utilization

- Green technology integration

- Material Optimization

- Eco-friendly packaging materials

- Reduced waste processes

- Recyclable components

- Sustainable practices

Maintenance and Support Considerations

Preventive Maintenance Strategies

Ensuring long-term system reliability through:

- Scheduled Maintenance

- Regular inspections

- Component replacement schedules

- System updates

- Performance optimization

- Condition Monitoring

- Real-time equipment monitoring

- Wear prediction

- Performance trending

- Early warning systems

Technical Support Framework

Establishing robust support systems:

- Remote Support

- Online troubleshooting

- Remote diagnostics

- Software updates

- Virtual assistance

- On-site Support

- Emergency response

- Regular service visits

- Training refreshers

- System upgrades

Integration with Industry 4.0

Digital Transformation

Embracing modern manufacturing concepts:

- Data Analytics

- Performance metrics

- Quality indicators

- Efficiency analysis

- Predictive modeling

- Connected Systems

- Enterprise resource planning integration

- Supply chain connectivity

- Digital twin technology

- Cloud-based management

Conclusion

The automation of steel coil packing lines represents a significant leap forward in manufacturing efficiency and quality control. By addressing the five common issues through advanced automated solutions, manufacturers can achieve substantial improvements in productivity, quality, and cost-effectiveness.

The key to success lies in careful implementation, comprehensive training, and ongoing support. As we've seen, the initial investment in automation technology can be significant, but the long-term benefits in terms of reduced waste, improved efficiency, and enhanced quality control make it a worthwhile investment for forward-thinking manufacturers.

Looking ahead, the integration of AI, IoT, and Industry 4.0 principles will continue to drive innovation in steel coil packing automation. Companies that embrace these technologies and maintain a commitment to continuous improvement will be well-positioned to compete in an increasingly demanding market.

The future of steel coil packing is automated, intelligent, and sustainable. By understanding and implementing these solutions, manufacturers can ensure their operations remain competitive, efficient, and ready for the challenges of tomorrow's industrial landscape.