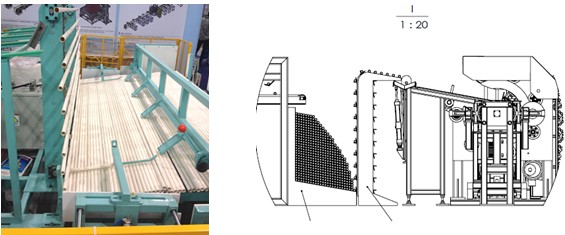

1.Storage & lifting system

It is for pipe collecting and storage, enable the operation of offline bundling, and ensure the working of the extruders uninterrupted. The pipe lifter is for lifting the pipe one by one and counting the pipe for bundling preparation. The machine can also be applied online connected with the pipe extruders.

Features:

1.Pipe accumulation and storage station.

2.Pipe lifter for lifting the pipe.

3.Pipe number counting.

4.Defective recycle storage device.

Automatic pipes aligning, stringing, strapping system.

Features:

Automatic pipe counting for bundling.

Excellent collections. Well-known brands adopted for main components.

Ring speed and conveyor speed adjustable by converters.

PLC&HMI program control for automation operation.

Both manual and automatic working mode can be choose.

Pipe aligning device for keeping the orderly ends.

The pipes are parallel without cross.

Supporting rollers are covered by polyurethane.

Stringing device adjustable per size of the pipe and bundle.

Automatic strapping for stringing pipes.

Strapping belt is adjustable per requirement.

Strapping position reset function.

The bundling system is adjustable for different pipe OD.

Pipe and bundle size:

Pipe Bundle diameter: ≤180mm

Conveying speed: 1-10m/min

Bundling speed: 20-60 pcs/min

Bundling material: LLDPE stretch film/PVC

Film roll size: OD:80-120mm; ID:50mm;

Width:60mm; thickness:25micron

Power supply: 380V, 3phase,60Hz

Air supply:4-8kgf/m2

3. Automatic conveying

Convey the pipe bundles to the gathering position automatically.

Features:

PLC program control.

Supporting rollers are covered by polyurethane

Automatic package outlet.

Conveyor speed is adjustable.