In the fast-paced world of manufacturing, efficiency and productivity are key to success. For industries that rely on the production and distribution of coiled materials, such as steel, wire, or cable, the process of packing and preparing these coils for shipping can be a critical bottleneck. This is where coil packing systems come into play, offering a range of solutions to streamline the packing process and improve overall operational efficiency.

Introduction

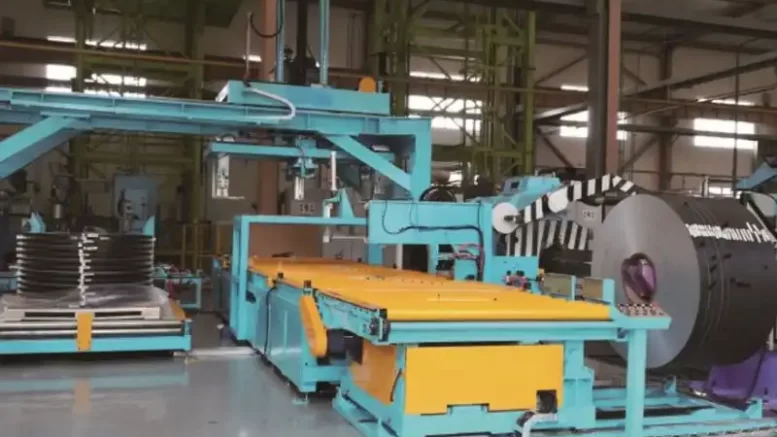

Coil packing systems are designed to automate and optimize the process of preparing coils for storage, transportation, and delivery. These systems can include a variety of components, such as wrapping machines, strapping machines, labeling systems, and material handling equipment, all working together to ensure that coils are properly protected, secured, and identified for their journey through the supply chain.

Heading 1: The Importance of Coil Packing

Before diving into the specifics of coil packing systems, it's essential to understand why proper coil packing is so crucial. Coiled materials, particularly those made from metal, are susceptible to damage during handling and transportation. Improper packing can lead to a range of issues, including:

- Physical damage: Coils that are not adequately protected can be scratched, dented, or deformed during loading, unloading, and transit. This damage can render the material unusable or require costly rework.

- Corrosion: Exposure to moisture, humidity, or other environmental factors can cause coils to corrode, leading to material degradation and potential customer rejections.

- Safety hazards: Poorly secured coils can shift during transportation, creating a safety risk for workers and potentially causing damage to other cargo or equipment.

By implementing effective coil packing systems, manufacturers can mitigate these risks and ensure that their products arrive at their destination in pristine condition.

Heading 2: Components of a Coil Packing System

A comprehensive coil packing system typically consists of several key components that work together to streamline the packing process. These components include:

- Wrapping machines: These machines are designed to apply protective wrapping material, such as plastic film or paper, around the coil. Wrapping helps to prevent damage from abrasion, moisture, and other environmental factors.

- Strapping machines: Strapping machines secure the wrapped coil with metal or plastic straps, ensuring that the wrapping remains tight and the coil is held securely in place.

- Labeling systems: Labeling systems apply identifying information to the coil, such as product codes, lot numbers, and customer information. This helps to ensure that coils are easily traceable and can be matched with the correct order.

- Material handling equipment: Coil packing systems often include material handling equipment, such as conveyors, lifts, and trolleys, to move coils efficiently through the packing process and prepare them for loading and shipping.

By integrating these components into a cohesive system, manufacturers can create a streamlined, efficient packing process that minimizes manual labor and reduces the risk of errors or damage.

Heading 3: Benefits of Automated Coil Packing Systems

Investing in an automated coil packing system offers a range of benefits for manufacturers, including:

- Increased efficiency: Automated systems can process coils much faster than manual methods, reducing the time required to pack each coil and increasing overall throughput.

- Improved consistency: Automated packing systems ensure that each coil is wrapped, strapped, and labeled in the same way, providing a consistent level of protection and identification.

- Reduced labor costs: By automating the packing process, manufacturers can reduce their reliance on manual labor, freeing up workers to focus on other value-added tasks.

- Enhanced safety: Automated systems minimize the need for workers to handle heavy coils manually, reducing the risk of injuries and creating a safer work environment.

- Better quality control: Integrated sensors and monitoring systems can detect issues with the packing process, such as misaligned wrapping or loose strapping, allowing for quick correction and reducing the likelihood of defects.

Heading 4: Choosing the Right Coil Packing System

When selecting a coil packing system, manufacturers must consider a range of factors to ensure that they choose a solution that meets their specific needs. Some key considerations include:

- Coil dimensions and weight: The size and weight of the coils being processed will dictate the type of equipment required, such as the size of the wrapping machine and the capacity of the material handling equipment.

- Production volume: The throughput requirements of the manufacturing operation will influence the speed and automation level needed in the coil packing system.

- Packaging requirements: Different industries and customers may have specific packaging requirements, such as the type of wrapping material or the number of straps required. The chosen system should be able to accommodate these requirements.

- Integration with existing equipment: The coil packing system should be compatible with the manufacturer's existing production equipment and processes, ensuring a smooth integration and minimizing disruption to operations.

- Budget and ROI: Manufacturers must balance the upfront cost of the coil packing system with the long-term benefits and return on investment. Consider factors such as reduced labor costs, increased efficiency, and improved product quality when evaluating the financial impact of the investment.

Heading 5: Coil Packing Automation and Industry 4.0

As the manufacturing industry continues to embrace the principles of Industry 4.0, coil packing systems are evolving to incorporate advanced technologies and data-driven processes. Some examples of how Industry 4.0 is transforming coil packing include:

- IoT sensors: Sensors embedded in the packing equipment can monitor various parameters, such as wrapping tension, strap tightness, and equipment performance, providing real-time data for process optimization and predictive maintenance.

- Machine learning: Advanced algorithms can analyze data from the coil packing process to identify patterns, optimize settings, and improve overall equipment effectiveness (OEE).

- Robotics: Collaborative robots (cobots) can be integrated into the packing process to perform tasks such as coil handling, wrapping, and strapping, working alongside human operators to increase efficiency and flexibility.

- Digital twin technology: Creating a digital twin of the coil packing system allows manufacturers to simulate process changes, optimize equipment layout, and train operators in a virtual environment before implementing changes in the real world.

By embracing these technologies, manufacturers can create a more agile, responsive, and data-driven coil packing process that can adapt to changing market demands and drive continuous improvement.

Heading 6: Sustainability and Environmental Considerations

As businesses increasingly prioritize sustainability and environmental responsibility, manufacturers must consider the impact of their coil packing processes. Fortunately, modern coil packing systems offer a range of opportunities to reduce waste, minimize energy consumption, and promote the use of eco-friendly materials.

- Recyclable packaging materials: Manufacturers can opt for wrapping and strapping materials that are recyclable or biodegradable, such as paper-based wraps or recycled plastic straps. This helps to reduce the environmental impact of the packing process and supports the circular economy.

- Optimized material usage: Advanced coil packing systems can optimize the use of wrapping and strapping materials, minimizing waste and reducing the overall environmental footprint of the packing process.

- Energy-efficient equipment: Modern coil packing equipment is designed with energy efficiency in mind, incorporating features such as low-energy motors, regenerative braking systems, and optimized pneumatic systems to reduce energy consumption and associated carbon emissions.

- Sustainable logistics: By optimizing the coil packing process, manufacturers can reduce the overall size and weight of packaged coils, enabling more efficient transportation and reducing the carbon footprint of the supply chain.

Heading 7: Maintenance and Support for Coil Packing Systems

To ensure the long-term performance and reliability of a coil packing system, manufacturers must prioritize regular maintenance and have access to comprehensive support from their equipment provider. Some key considerations include:

- Preventive maintenance: Implementing a preventive maintenance schedule helps to minimize unplanned downtime, extend equipment lifespan, and ensure consistent performance. This can include tasks such as regular cleaning, lubrication, and component inspections.

- Training and documentation: Ensuring that operators are properly trained on the use and maintenance of the coil packing system is essential for optimal performance and safety. Detailed documentation, including user manuals and maintenance guides, should be readily available to support ongoing operation and troubleshooting.

- Remote support and monitoring: Many modern coil packing systems offer remote support capabilities, allowing equipment providers to monitor system performance, diagnose issues, and provide remote assistance to minimize downtime and ensure rapid resolution of any problems.

- Spare parts management: Maintaining an inventory of critical spare parts and consumables ensures that the coil packing system can be quickly repaired or maintained in the event of a breakdown, minimizing the impact on production schedules.

Heading 8: Integration with Warehouse Management Systems

To fully optimize the coil packing process and streamline the entire supply chain, manufacturers should consider integrating their coil packing system with a warehouse management system (WMS). A WMS can provide a range of benefits, including:

- Inventory tracking: A WMS can track coils from the moment they are produced until they are shipped, providing real-time visibility into inventory levels, locations, and movements.

- Order management: By integrating the coil packing system with a WMS, manufacturers can automatically generate packing lists and shipping labels based on customer orders, reducing the risk of errors and improving order accuracy.

- Traceability: A WMS can record detailed information about each coil, such as production date, lot number, and quality data, enabling manufacturers to trace coils through the supply chain and quickly respond to any quality issues or customer inquiries.

- Analytics and reporting: A WMS can provide valuable data and analytics on the performance of the coil packing process, helping manufacturers to identify bottlenecks, optimize resource allocation, and drive continuous improvement.

Heading 9: Customization and Flexibility

Every manufacturing operation is unique, with its own specific requirements and challenges. As such, it's essential to choose a coil packing system that offers a high degree of customization and flexibility to meet the needs of the business. Some key considerations include:

- Modular design: A modular coil packing system allows manufacturers to add, remove, or modify components as their needs change, ensuring that the system can grow and adapt with the business.

- Customizable settings: Adjustable parameters, such as wrapping tension, strap tension, and conveyor speeds, allow manufacturers to fine-tune the packing process to suit different coil types, sizes, and packaging requirements.

- Integration with custom equipment: The ability to integrate the coil packing system with custom equipment, such as specialized conveyors or material handling devices, ensures that the system can be tailored to the specific needs of the manufacturing operation.

- Scalability: As production volumes grow, the coil packing system should be able to scale up to meet increased demand without requiring significant additional investment or modifications.

Heading 10: The Future of Coil Packing Systems

As technology continues to advance and the demands of the manufacturing industry evolve, coil packing systems are poised to become even more sophisticated, efficient, and intelligent. Some trends and developments to watch include:

- Artificial intelligence: AI-powered coil packing systems could autonomously optimize packing processes, predict maintenance needs, and adapt to changing production requirements in real-time.

- 5G connectivity: The rollout of 5G networks will enable even faster data transmission and processing, allowing for more responsive, data-driven coil packing systems that can communicate seamlessly with other equipment and systems.

- Augmented reality: AR technology could be used to provide real-time guidance and support to operators, displaying relevant information and instructions directly in their field of view.

- Sustainable materials: As the focus on environmental sustainability grows, the development of new, eco-friendly packaging materials and technologies will become increasingly important, driving innovation in coil packing systems.

Conclusion

In today's competitive manufacturing landscape, optimizing the coil packing process is essential for businesses looking to improve efficiency, reduce costs, and enhance customer satisfaction. By investing in advanced coil packing systems that incorporate automation, data-driven decision-making, and flexible design, manufacturers can streamline their operations, minimize waste, and ensure that their products are delivered to customers in pristine condition.

As the industry continues to evolve and new technologies emerge, coil packing systems will play an increasingly critical role in driving innovation, sustainability, and competitiveness. By staying at the forefront of these developments and partnering with experienced equipment providers, manufacturers can position themselves for success in the years ahead, able to adapt to changing market demands and deliver the highest quality products to their customers.