In the world of coil packaging, a one-size-fits-all approach rarely yields the best results. Every business has unique requirements, from coil dimensions and materials to production volume and facility layout. This is where customization comes into play, allowing you to tailor your coil packing line to your specific needs. By investing in a custom-designed solution, you can unlock a host of benefits that can greatly impact your efficiency, productivity, and bottom line.

1. Optimizing for Your Coil Specifications

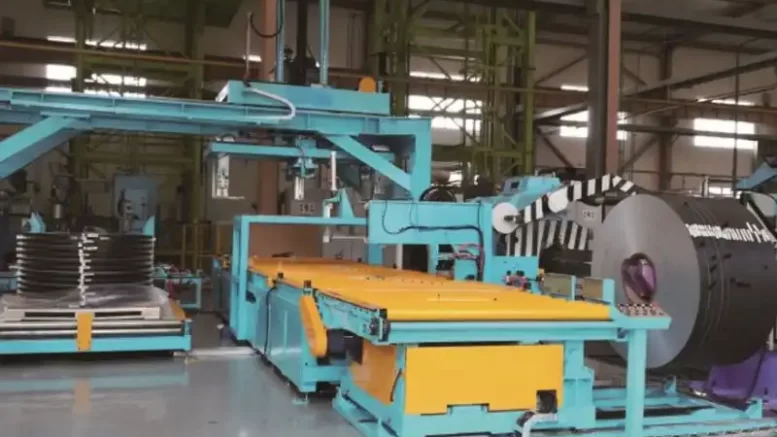

One of the primary advantages of customizing your coil packing line is the ability to optimize it for your specific coil specifications. Whether you're dealing with steel, aluminum, copper, or other materials, and regardless of the coil size or weight, a customized coil packaging line can be engineered to handle your products with precision and care. This optimization ensures that your coils are properly supported, protected, and packaged, minimizing the risk of damage during handling and transportation. By tailoring your line to your exact requirements, you can improve product quality, reduce waste, and enhance customer satisfaction.

2. Maximizing Throughput and Efficiency

Throughput, or the number of coils processed per hour, is a critical factor in determining the efficiency of your packing line. A customized solution can be designed to maximize throughput based on your specific production needs and goals. By carefully analyzing your current and projected volumes, facility layout, and staffing levels, a custom line can be engineered to optimize workflow, minimize bottlenecks, and ensure smooth, uninterrupted operation. This increased efficiency translates to higher productivity, faster turnaround times, and improved profitability, giving you a competitive edge in the market.

3. Seamless Integration with Existing Systems

Another significant benefit of customization is the ability to seamlessly integrate your coil packing line with your existing systems and infrastructure. Every facility is unique, with its own layout, material handling equipment, storage solutions, and IT systems. A custom-designed packing line can be tailored to work in harmony with these existing elements, ensuring a smooth transition and minimizing disruption to your operations. This integration can encompass everything from conveyors and cranes to software and control systems, allowing for streamlined data exchange, real-time monitoring, and enhanced visibility across your entire packaging process.

4. Flexibility for Future Growth and Changes

Investing in a customized coil packing line not only addresses your current needs but also provides flexibility for future growth and changes. As your business evolves, your packaging requirements may shift, whether due to new product offerings, increased production volumes, or changing customer demands. A custom-designed solution can be engineered with scalability and adaptability in mind, allowing you to easily modify, expand, or reconfigure your line as needed. This future-proofing ensures that your investment continues to deliver value and support your growth over the long term, without the need for costly replacements or extensive modifications.

5. Tailored Automation and Technology

Customization also allows you to tailor the level of automation and technology in your coil packing line to your specific needs and budget. From fully automated systems to semi-automatic or manual solutions, a custom-designed line can incorporate the right balance of advanced features and human intervention to optimize your operations. This tailored approach ensures that you're investing in technology that delivers the greatest value for your business, whether through increased speed, reduced labor costs, improved accuracy, or enhanced data collection and analysis capabilities. By strategically incorporating automation and technology, you can streamline your processes, boost efficiency, and gain a competitive advantage in your market.

6. Enhanced Safety and Ergonomics

Customizing your coil packing line presents a valuable opportunity to prioritize and enhance safety and ergonomics in your facility. By tailoring your equipment to your specific needs, you can incorporate safety features and ergonomic design elements that minimize the risk of accidents, injuries, and strain on your workers. This can include adjustable workstations, automated material handling, safety guarding, and intuitive controls that reduce physical demands and promote a safer, more comfortable work environment. By investing in a custom solution that prioritizes safety and ergonomics, you can improve employee well-being, reduce lost time incidents, and boost morale and productivity across your packaging operations.

7. Optimized Material Usage and Waste Reduction

Efficient material usage and waste reduction are key considerations in any packaging operation, and a customized coil packing line can help you optimize both. By tailoring your equipment to your specific coil sizes, shapes, and packaging requirements, you can minimize excess material usage, reduce scrap, and improve overall resource efficiency. Custom-designed solutions can incorporate precise measuring and dispensing systems, adaptive tensioning controls, and smart cutting technologies that ensure optimal material application and minimize waste. These enhancements not only reduce your environmental footprint but also lead to significant cost savings over time, as you optimize your packaging materials and minimize disposal costs.

8. Brand Differentiation and Packaging Customization

In today's competitive marketplace, brand differentiation is more important than ever. A customized coil packing line allows you to create unique, branded packaging solutions that set your products apart and make a lasting impression on your customers. By tailoring your equipment to accommodate custom printing, labeling, and packaging designs, you can showcase your brand identity, convey key product information, and create a professional, cohesive look across your product lines. This level of packaging customization not only enhances your brand recognition but also helps to build customer trust, loyalty, and perceived value, ultimately driving sales and growth for your business.

9. Improved Maintenance and Serviceability

Ease of maintenance and serviceability are critical factors in the long-term performance and reliability of your coil packing line. A customized solution can be designed with maintenance and service requirements in mind, incorporating features that streamline these processes and minimize downtime. This can include modular components, accessible service points, standardized parts, and intuitive diagnostic systems that simplify troubleshooting and repairs. By optimizing your equipment for maintainability, you can reduce service costs, improve response times, and ensure maximum uptime for your packaging operations. Additionally, working with a custom equipment provider often comes with the added benefit of personalized support, training, and service programs that keep your line running smoothly and efficiently.

10. Competitive Advantage and Long-Term ROI

Investing in a customized coil packing line is a strategic decision that can provide a significant competitive advantage and long-term return on investment (ROI) for your business. By tailoring your equipment to your unique needs, you can optimize your packaging process, improve product quality, increase efficiency, and reduce costs in ways that off-the-shelf solutions simply cannot match. This level of customization allows you to adapt to changing market demands, capitalize on new opportunities, and differentiate your offerings from competitors. While the initial investment in a custom line may be higher than a standard solution, the long-term benefits in terms of increased productivity, reduced waste, enhanced brand value, and improved customer satisfaction can far outweigh the upfront costs, delivering a substantial ROI over the life of the equipment.

Conclusion

Customizing your coil packing line is a transformative approach that can greatly impact your packaging operations, from optimizing for your specific coil specifications and maximizing throughput to enhancing safety, reducing waste, and strengthening your brand identity. By tailoring your equipment to your unique needs, you can unlock a host of benefits that drive efficiency, productivity, and profitability, while also future-proofing your investment and gaining a competitive edge in your market. While the path to customization may require careful planning and investment, the long-term advantages and ROI potential make it a strategic choice for businesses looking to optimize their coil packaging process, adapt to evolving demands, and achieve sustainable growth in an increasingly competitive landscape. By embracing the power of customization, you can transform your coil packing line into a key driver of success and innovation for your business.