Hey there, steel industry pros! Let's talk about something that's probably been on your mind lately – your steel coil packing line. You know, that workhorse of your operation that's been humming along for years. But here's the million-dollar question: Is it time for an upgrade? Don't worry, we're going to dive deep into this topic and help you figure it out. Grab a cup of coffee, and let's get started!

The Telltale Signs of an Aging Packing Line

First things first, let's look at some dead giveaways that your steel coil packing line might be crying out for an upgrade.

1. Slower Production Speeds

Remember when your line used to zip through coils like a hot knife through butter? If you're noticing a significant slowdown, it might be time to consider an upgrade. Modern packing lines are designed for speed without compromising on quality. If you're constantly tapping your foot waiting for coils to be packed, that's productivity (and money) going down the drain.

2. Increased Downtime

Ah, downtime – the bane of every production manager's existence. If your maintenance team is on a first-name basis with your packing line, spending more time fixing it than it spends actually packing, you've got a problem. Newer systems are built with reliability in mind, meaning less downtime and more production time.

3. Quality Issues

Steel coils are your bread and butter, and their packaging is their armor. If you're seeing an uptick in customer complaints about damaged goods, your packing line might be the culprit. Modern packing lines offer superior protection, ensuring your coils arrive at their destination in pristine condition.

4. Energy Inefficiency

Let's talk about your electricity bill for a second. If it's starting to look like a small country's GDP, your old packing line might be the energy-guzzling culprit. Newer models are designed with energy efficiency in mind, potentially saving you a small fortune in the long run.

The Tech Revolution in Steel Coil Packing

Now, let's geek out a bit and look at some of the cool tech that's revolutionizing the steel coil packing game.

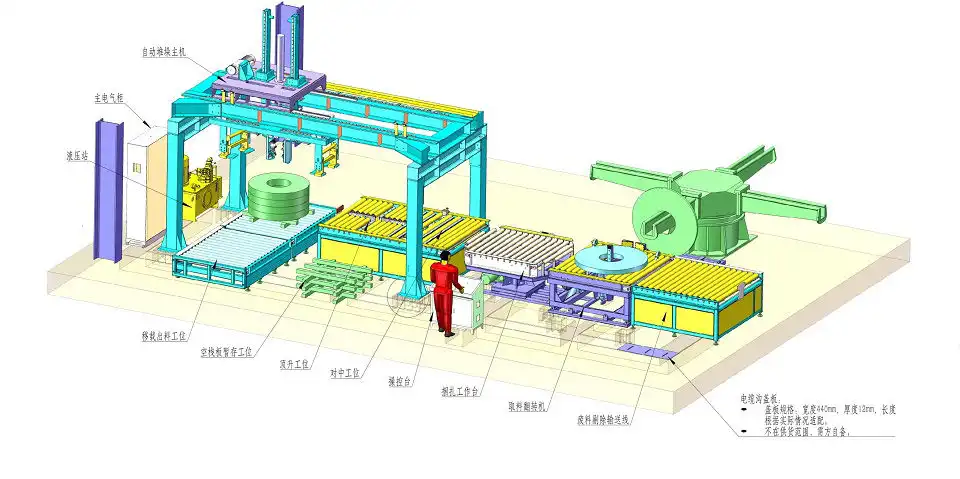

5. Automation Advancements

Gone are the days of manual labor dominating the packing process. Today's packing lines are a symphony of robotic arms, automated guided vehicles (AGVs), and smart conveyor systems. These systems not only speed up the process but also reduce the risk of human error and workplace injuries.

6. Smart Sensors and IoT Integration

Imagine a packing line that could tell you it needs maintenance before it breaks down. That's the power of smart sensors and Internet of Things (IoT) technology. These systems can monitor everything from temperature to vibration, giving you real-time insights into your line's performance and helping predict maintenance needs.

7. Advanced Materials in Packaging

The materials used in steel coil packaging have come a long way. We're talking high-tech wraps that offer better protection against moisture, corrosion, and physical damage. If your current line can't handle these new materials, you might be missing out on providing top-notch protection for your products.

The Business Case for Upgrading

Alright, let's put on our business hats for a moment and look at why upgrading your steel coil packing line makes solid financial sense.

8. Increased Throughput

Time is money, especially in the steel industry. A modern, high-speed packing line can significantly increase your throughput. We're talking about packing more coils in less time, which means you can take on more orders and boost your bottom line.

9. Reduced Labor Costs

With increased automation comes reduced reliance on manual labor. While this doesn't mean replacing your workforce, it does mean you can reallocate your human resources to more value-added tasks. Your skilled workers can focus on quality control, process improvement, and other areas that require human expertise.

10. Enhanced Product Quality

Better packaging means happier customers, and happy customers mean repeat business. By upgrading to a packing line that offers superior protection, you're not just selling steel coils – you're selling peace of mind. This can give you a competitive edge in a crowded market.

Assessing Your Current Setup

Before you start shopping for a new packing line, it's crucial to take a good, hard look at your current setup. Here's how to do a thorough assessment:

11. Performance Metrics Analysis

Start by gathering data on your current line's performance. Look at metrics like:

- Coils packed per hour

- Downtime frequency and duration

- Defect rates

- Energy consumption

Compare these numbers to industry standards and your production goals. If you're falling short, it might be time for an upgrade.

12. Cost-Benefit Analysis

Upgrading a steel coil packing line is a significant investment. Do a detailed cost-benefit analysis that includes:

- Initial cost of the new equipment

- Installation and training costs

- Projected energy savings

- Estimated increase in productivity

- Potential reduction in labor costs

- Expected decrease in product damage claims

If the numbers show a positive ROI within a reasonable timeframe, you've got a strong case for upgrading.

That's the first half of our deep dive into determining if your steel coil packing line needs an upgrade. We've covered the signs of an aging line, the latest tech advancements, the business case for upgrading, and how to assess your current setup. In the second half, we'll explore compatibility issues, future-proofing your investment, and the step-by-step process of planning and implementing an upgrade. Stay tuned!

Compatibility Considerations

When upgrading your steel coil packing line, it's crucial to ensure that the new equipment will play nice with your existing setup. Let's break this down:

13. Integration with Existing Systems

Your packing line doesn't exist in isolation. It needs to work seamlessly with other systems in your production flow. Here are some key points to consider:

- Data Integration: Can the new line communicate with your existing ERP or MES systems?

- Physical Layout: Will the new equipment fit into your current floor plan, or will you need to reconfigure your space?

- Power Requirements: Does your facility have the electrical capacity to support the new equipment?

- Upstream and Downstream Compatibility: Will the upgraded line match the speed and capabilities of your other production processes?

Remember, the goal is to enhance your overall production flow, not create a bottleneck elsewhere in the system.

Future-Proofing Your Investment

When you're dropping serious cash on a new steel coil packing line, you want to make sure it's not going to be obsolete in a few years. Here's how to future-proof your investment:

14. Scalability and Flexibility

The steel industry is known for its ups and downs. Your new packing line should be able to handle both boom times and lean periods. Look for systems that offer:

- Modular Design: Can you easily add or remove components as your needs change?

- Adjustable Speed: Can the line operate efficiently at various speeds to match demand?

- Product Variety: Can it handle different coil sizes and packaging requirements?

15. Technology Roadmap

When evaluating potential upgrades, don't just look at what the equipment can do today. Ask suppliers about their technology roadmap:

- What upgrades or new features are planned for the next 3-5 years?

- How easy is it to update software or add new capabilities?

- What's the expected lifespan of the equipment?

Investing in a system with a clear path for future enhancements can save you from needing another major upgrade too soon.

The Upgrade Process: Planning and Implementation

Alright, you've decided an upgrade is in order. Now what? Let's break down the process step by step:

16. Needs Assessment and Goal Setting

Before you start shopping for new equipment, clearly define what you need:

- What are your specific production goals?

- What problems are you trying to solve?

- What new capabilities do you want to add?

Be as specific as possible. Instead of "we want to pack faster," aim for "we need to increase our packing speed by 30% to meet projected demand."

17. Research and Vendor Selection

Now it's time to hit the market:

- Industry Research: Attend trade shows, read industry publications, and talk to peers about the latest in steel coil packing technology.

- Vendor Comparison: Don't just look at equipment specs. Consider factors like after-sales support, spare parts availability, and the vendor's financial stability.

- Site Visits: If possible, visit facilities using the equipment you're considering. There's no substitute for seeing a line in action.

18. Financial Planning

Upgrading a packing line is a major capital expenditure. Work closely with your finance team to:

- Explore financing options (purchase, lease, etc.)

- Consider tax implications and potential incentives for upgrading to more energy-efficient equipment

- Develop a detailed budget that includes not just the equipment cost, but also installation, training, and potential production disruptions during the transition

19. Implementation Strategy

Once you've selected your new equipment, it's time to plan the implementation:

- Timeline: Develop a realistic timeline for delivery, installation, and commissioning.

- Training: Plan comprehensive training for operators and maintenance staff.

- Contingency Planning: Have a backup plan for meeting production demands during the installation and testing phase.

20. Post-Implementation Evaluation

The job's not done once the new line is up and running. Plan for a thorough evaluation:

- Set up a system to track key performance indicators (KPIs) and compare them to your pre-upgrade metrics.

- Schedule regular check-ins with operators and maintenance staff to gather feedback.

- Be prepared to make adjustments and fine-tune the system based on real-world performance.

The Human Factor: Preparing Your Team for Change

Let's not forget the most important part of any upgrade – your people. A successful upgrade isn't just about installing new equipment; it's about ensuring your team is ready and excited for the change.

21. Communication is Key

From the moment you start considering an upgrade, keep your team in the loop:

- Explain why the upgrade is necessary and how it will benefit the company (and them).

- Address concerns about job security openly and honestly.

- Encourage feedback and suggestions from the floor – your operators often have invaluable insights.

22. Training and Skill Development

A new steel coil packing line often means new skills are needed. Invest in your team:

- Develop a comprehensive training program that covers both operation and basic maintenance.

- Consider cross-training to increase flexibility in your workforce.

- Look for opportunities to upskill workers whose roles might be changed by increased automation.

Conclusion: Embracing the Future of Steel Coil Packing

Whew! We've covered a lot of ground, haven't we? From recognizing the signs that your steel coil packing line needs an upgrade to planning and implementing that upgrade, we've explored every angle of this crucial decision.

Remember, upgrading your packing line isn't just about keeping up with the Joneses – it's about positioning your business for future success. It's about increasing efficiency, improving product quality, and staying competitive in an ever-evolving industry.

As you consider whether an upgrade is right for your operation, keep these key points in mind:

- Assess honestly: Take a hard look at your current performance and future needs.

- Think long-term: Choose solutions that will grow with your business.

- Plan thoroughly: From financing to implementation, leave no stone unturned in your planning.

- Involve your team: Your people are your greatest asset – make sure they're on board and prepared for the change.

The steel industry has always been about strength and durability. By keeping your steel coil packing line up to date, you're ensuring that your business embodies those same qualities – strong enough to meet today's challenges and durable enough to thrive well into the future.

So, is it time for an upgrade? Only you can answer that question for your specific situation. But armed with the insights from this guide, you're now well-equipped to make an informed decision that will set your steel coil packing operation up for success for years to come.