Investing in an automatic coil packing line is a significant decision for any steel processing business. While the initial cost may seem substantial, the long-term benefits and cost savings can far outweigh the investment. This comprehensive guide will walk you through the process of justifying the cost of an automatic coil packing line, highlighting the key factors to consider and providing a practical framework for evaluating the return on investment (ROI).

Heading 1: Assess Your Current Packing Process

Style: Analytical, Process-Oriented

Before considering an investment in an automatic coil packing line, it's essential to thoroughly assess your current packing process. This assessment will provide a baseline for comparison and help you identify areas where automation can deliver the most significant improvements. Consider the following factors:

- Manual Labor Costs: Evaluate the cost of manual labor involved in your current packing process, including wages, benefits, and overtime. Consider the number of workers required to handle the packing tasks and the time spent on each coil.

- Packing Speed and Throughput: Measure the average time it takes to pack a single coil manually and calculate your current hourly or daily throughput. This data will serve as a benchmark to compare against the potential speed and throughput of an automatic packing line.

- Packing Material Costs: Assess the cost of packaging materials used in your current process, such as wrapping, strapping, and protective materials. Consider any waste or inefficiencies in material usage that could be minimized with an automated system.

- Error Rates and Rework: Evaluate the frequency of packing errors, such as incorrect labeling, inadequate wrapping, or damage during handling. Estimate the cost of rework, including the time and materials required to correct these errors.

- Safety and Ergonomic Concerns: Consider any safety risks or ergonomic issues associated with manual packing, such as lifting heavy coils or repetitive strain injuries. Assess the potential costs of worker's compensation claims, lost productivity, and absenteeism related to these concerns.

By thoroughly assessing your current packing process, you can identify the key areas where an automatic coil packing line can deliver improvements and cost savings, providing a strong foundation for justifying the investment.

Heading 2: Define Your Packing Requirements and Goals

Style: Goal-Oriented, Strategic

Once you have assessed your current packing process, the next step is to define your specific packing requirements and goals. Clearly articulating your objectives will help you evaluate the potential benefits of an automatic coil packing line and align the investment with your overall business strategy. Consider the following factors:

- Production Volume and Scalability: Determine your current production volume and anticipated growth in the coming years. Consider whether your packing process needs to accommodate increased demand or adapt to fluctuations in order volume.

- Coil Dimensions and Variability: Specify the range of coil dimensions, including width, diameter, and weight, that your packing process must handle. Consider any variability in coil sizes and the need for flexibility in your packing setup.

- Packaging Quality and Consistency: Define your desired level of packaging quality and consistency, including factors such as wrapping tightness, label accuracy, and overall product protection. Consider any specific customer requirements or industry standards that your packaging must meet.

- Efficiency and Productivity Targets: Set clear targets for improving packing efficiency and productivity, such as increasing throughput, reducing cycle times, or minimizing downtime. Quantify these targets to provide a measurable basis for evaluating the performance of an automatic packing line.

- Integration with Existing Systems: Consider how an automatic coil packing line would integrate with your existing production line, material handling equipment, and IT systems. Define any specific integration requirements or constraints that must be addressed during the implementation process.

By clearly defining your packing requirements and goals, you can establish a strong framework for evaluating the potential benefits and ROI of an automatic coil packing line, ensuring that the investment aligns with your business objectives and delivers the desired outcomes.

Heading 3: Research and Compare Automatic Coil Packing Line Options

Style: Comparative Analysis, Practical Guide

With a clear understanding of your current packing process and future goals, the next step is to research and compare the available automatic coil packing line options. There are various types of automatic packing lines on the market, each with its own features, capabilities, and price points. Consider the following factors when evaluating potential solutions:

- Packing Line Configuration: Assess the configuration options available, such as inline, L-shape, or U-shape layouts, to determine which best fits your facility layout and workflow. Consider the space requirements and any modifications needed to accommodate the packing line.

- Automation Level and Features: Evaluate the level of automation offered by each packing line, including features such as automatic coil loading, wrapping, strapping, and labeling. Determine which features are essential for your process and which ones offer the most significant benefits in terms of efficiency and quality.

- Packing Speed and Capacity: Compare the packing speed and capacity of different automatic packing lines, considering factors such as coils per hour, cycle times, and maximum coil dimensions. Ensure that the chosen solution can meet your current and future production requirements.

- Flexibility and Changeover: Assess the flexibility of each packing line in terms of handling different coil sizes and packaging configurations. Consider the ease and speed of changeovers between product runs and the potential impact on overall equipment effectiveness (OEE).

- Integration and Compatibility: Evaluate the compatibility of each packing line with your existing systems, such as production line equipment, material handling devices, and IT infrastructure. Consider any potential integration challenges or additional investments required to ensure seamless operation.

- Supplier Reputation and Support: Research the reputation and track record of each packing line supplier, considering factors such as industry experience, customer references, and after-sales support. Evaluate the availability of training, maintenance services, and spare parts to ensure long-term reliability and performance.

By thoroughly researching and comparing the available automatic coil packing line options, you can make an informed decision that balances your specific requirements, budget constraints, and long-term business goals. This comparative analysis will provide a strong foundation for justifying the investment and selecting the best solution for your steel processing operation.

Heading 4: Conduct a Financial Analysis and ROI Calculation

Style: Financial, Data-Driven

To justify the cost of an automatic coil packing line, it's crucial to conduct a thorough financial analysis and calculate the expected return on investment (ROI). This analysis will help you determine the economic viability of the investment and provide a clear picture of the potential cost savings and benefits. Consider the following steps:

- Initial Investment Costs: Determine the total initial investment required for the automatic packing line, including equipment purchase, installation, and any necessary facility modifications. Obtain detailed quotes from suppliers and factor in any additional costs, such as training or software integration.

- Operating Cost Savings: Estimate the potential operating cost savings achieved by implementing an automatic packing line. Consider factors such as reduced manual labor costs, increased productivity, improved material utilization, and minimized rework and waste. Quantify these savings based on your current packing process assessment and the capabilities of the chosen packing line.

- Throughput and Capacity Gains: Calculate the expected throughput and capacity gains achieved by automating the packing process. Determine how these gains translate into increased production volume, shorter lead times, and improved responsiveness to customer demands. Quantify the potential revenue growth and market share expansion resulting from these improvements.

- Maintenance and Upkeep Costs: Estimate the ongoing maintenance and upkeep costs associated with the automatic packing line, including scheduled servicing, spare parts, and any necessary upgrades or modifications. Factor these costs into your financial analysis to ensure a comprehensive understanding of the long-term financial impact.

- ROI Calculation: Use the gathered financial data to calculate the expected ROI of the automatic coil packing line investment. Determine the payback period, net present value (NPV), and internal rate of return (IRR) to assess the financial attractiveness of the project. Compare these metrics against your company's investment criteria and benchmark them against industry standards.

By conducting a rigorous financial analysis and ROI calculation, you can provide a compelling economic justification for the investment in an automatic coil packing line. This data-driven approach will help you gain stakeholder buy-in and secure the necessary funding for the project.

Heading 5: Build a Compelling Business Case

Style: Persuasive, Executive-Level

Armed with the insights from your current process assessment, packing requirements and goals, comparative analysis, and financial evaluation, the final step is to build a compelling business case for investing in an automatic coil packing line. A well-structured and persuasive business case will help you communicate the value of the investment to key decision-makers and stakeholders. Consider the following elements:

- Executive Summary: Begin with a concise executive summary that highlights the key points of your business case, including the problem statement, proposed solution, expected benefits, and financial projections. This summary should capture the attention of busy executives and provide a clear overview of the investment opportunity.

- Current Process Challenges: Clearly articulate the challenges and limitations of your current packing process, emphasizing the impact on productivity, quality, safety, and customer satisfaction. Use data and examples to illustrate the magnitude of these challenges and the need for improvement.

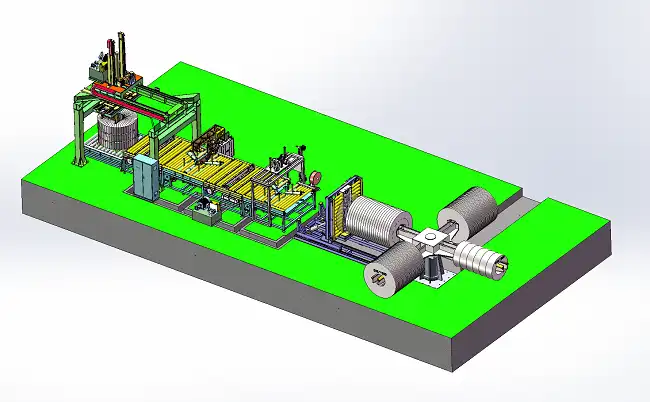

- Solution Overview: Present the proposed automatic coil packing line as the optimal solution to address the identified challenges. Highlight the key features and capabilities of the chosen packing line, emphasizing how they align with your specific packing requirements and goals.

- Benefits and Improvements: Outline the expected benefits and improvements achieved by implementing the automatic packing line, including increased efficiency, enhanced product quality, improved safety and ergonomics, and reduced environmental impact. Quantify these benefits wherever possible, using the insights from your comparative analysis and financial evaluation.

- Financial Justification: Present the results of your financial analysis and ROI calculation, demonstrating the economic viability of the investment. Highlight the expected cost savings, revenue growth, and payback period, and compare these metrics against your company's investment criteria. Use visuals, such as graphs and charts, to effectively communicate the financial impact.

- Implementation Plan: Outline a high-level implementation plan for the automatic coil packing line, including key milestones, timelines, and resource requirements. Identify any potential risks or challenges and present mitigation strategies to address them. Demonstrate your commitment to a smooth and successful implementation process.

- Conclusion and Recommendation: Conclude your business case with a clear and persuasive recommendation to invest in the automatic coil packing line. Summarize the key benefits, financial projections, and strategic alignment of the investment, and emphasize the importance of taking action to secure the long-term competitiveness and success of your steel processing operation.

By building a compelling business case that combines strategic, operational, and financial perspectives, you can effectively justify the cost of an automatic coil packing line and gain the necessary support and approval from key decision-makers. This comprehensive approach will position your investment proposal for success and pave the way for a transformative improvement in your steel coil packing process.

Conclusion

Justifying the cost of an automatic coil packing line requires a thorough and multifaceted approach that addresses the strategic, operational, and financial aspects of the investment. By assessing your current packing process, defining your requirements and goals, researching and comparing available options, conducting a financial analysis, and building a compelling business case, you can effectively demonstrate the value and feasibility of the investment.

An automatic coil packing line offers significant benefits, including increased efficiency, enhanced product quality, improved safety and ergonomics, and reduced environmental impact. By automating your packing process, you can unlock substantial cost savings, boost productivity, and position your steel processing operation for long-term success in an increasingly competitive market.

The key to justifying the cost lies in presenting a data-driven, persuasive case that resonates with decision-makers and stakeholders. By highlighting the alignment between the investment and your company's strategic objectives, quantifying the expected benefits and ROI, and demonstrating a clear implementation plan, you can build a strong foundation for securing the necessary support and funding.

In today's fast-paced and innovation-driven steel industry, investing in advanced technologies like automatic coil packing lines is no longer a luxury but a necessity. By taking a proactive approach to modernizing your packing process, you can stay ahead of the curve, differentiate your business from competitors, and deliver exceptional value to your customers. The time to act is now – embrace the power of automation and take your steel coil packing process to the next level.