Introduction to Steel Coil Packaging

Efficient steel coil packaging reduces damages, cuts costs, and boosts productivity. Companies must adopt innovative solutions to stay competitive. This article explores essential packaging methods for steel coils.

Steel coil packaging is crucial for preventing damage during transport, maintaining product quality, and ensuring efficient handling. Proper packaging minimizes risks, reduces costs, and meets industry standards, making it indispensable for companies seeking to enhance their operational efficiency and customer satisfaction.

In my four decades of industry experience, I've witnessed how correct packaging can transform operations. Let's delve into the significance of steel coil packaging and why it matters so much.

Why is steel coil packaging important?

Proper packaging shields steel coils from potential damages, improves logistics efficiency, and enhances client relations. Companies failing in this area may face unnecessary losses and operational bottlenecks.

Effective steel coil packaging protects the product during transportation and storage. It minimizes potential damages and wastage while ensuring the coils are easy to handle, safe, and compliant with industry regulations. Implementing robust packaging practices is critical for maintaining quality and optimizing operational efficiency.

Unpacking the Necessity of Steel Coil Packaging

Back when I started, I learned first-hand the impact of carelessly packaged steel coils. Small dents or exposure to moisture seemed trivial initially. But eventually, it led to large-scale losses and client dissatisfaction. As a solution-seeker, I focused on innovative packaging techniques that addressed these challenges head-on. Here, we explore critical aspects that reinforce the importance of steel coil packaging:

Why Effective Packaging Matters

Consider the data below illustrating damages resulting from improper packaging practices, emphasizing the necessity of sound packaging solutions:

| Packaging Type | Damage Rate (%) | Cost Implication ($) |

|---|---|---|

| Inadequate | 15 | 50,000 |

| Standard | 8 | 25,000 |

| Advanced | 2 | 5,000 |

The table shows how a slight increase in direct investment in advanced packaging can significantly decrease damage rates and subsequent costs. These figures underline the urgency of adopting reliable packaging methods to safeguard against losses and inefficiency.

Throughout my career, I've frequently discussed packaging strategies with fellow engineers and managers like David, our imaginary 42-year-old purchasing manager. People like David understand incorporating high-end packaging systems not only saves money but boosts productivity and client satisfaction in the long run. Investing in comprehensive steel coil packaging solutions yields decreased damage rates, better handling during storage and transit, and forms a foundation for robust client relations.

2. What are the common methods used in steel coil packaging?

Packaging steel coils efficiently remains a key challenge for manufacturers seeking to balance durability, protection, and cost-effectiveness in a competitive market.

Common steel coil packaging methods include stretch wrapping, strapping, and using protective materials. These methods safeguard coils during transit and storage, ensuring they remain undamaged while minimizing costs.

Understanding Different Packaging Techniques

Several techniques contribute to effective steel coil packaging, each offering unique benefits. Let's examine the most prominent methods to understand their applications and effectiveness.

| Method | Description | Advantages |

|---|---|---|

| Stretch Wrapping | Coils are wrapped with multiple layers of plastic film. | Protects against moisture and dust. Provides excellent load stability. |

| Strapping | Uses metal or plastic straps to secure coils in place. | Offers high tension and strength. Ideal for heavy loads. |

| Protective Materials | May include VCI papers, edge protectors, and coated fabrics. | Adds cushioning and prevents abrasion. Guards against corrosion. |

Stretch wrapping involves using elastic plastic film, forming a tight protective layer to shield coils from environmental factors like moisture and dust. It's especially beneficial for maintaining load stability during transportation. Strapping uses robust metal or plastic straps, effectively preventing coil movement and offering high tension and strength, making it ideal for heavy coils. Protective materials play a crucial role as well, with corrosion inhibitors and edge protectors providing an additional layer of safety during transport and long-term storage. By employing these methods, manufacturers can ensure coils arrive at their destination intact, thus safeguarding their investment and reputation.

3. How are innovations shaping the future of steel coil packaging?

Rapid technological advancements in the packaging sector present opportunities to enhance the efficiency and safety of steel coil handling and storage.

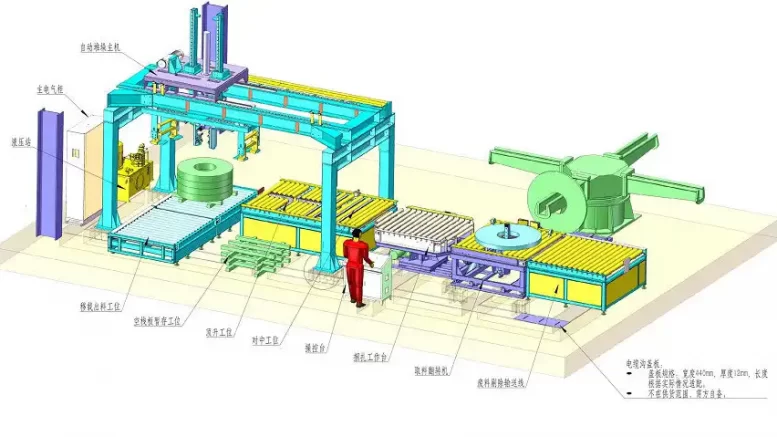

Innovations in steel coil packaging focus on automation and smart technologies, improving precision and consistency. These advances reduce manual labor and errors, increasing productivity and safety across operations.

Evaluating the Impact of Technological Advancements

Technological progress is redefining steel coil packaging, integrating automation and smart technologies for improved operations.

| Innovation | Impact | Benefits |

|---|---|---|

| Automation | Streamlines packaging processes by reducing manual intervention. | Increases productivity and reduces labor costs. |

| Smart Sensors | Monitors environmental conditions and coil integrity in real-time. | Enhances quality control and prevents damage. |

| Robotics | Handles coil movement and placement with precision. | Minimizes human error and maximizes safety. |

Automation is streamlining packaging processes, minimizing manual handling, and thus enhancing productivity. With the integration of smart sensors, environmental conditions like temperature and humidity are monitored in real-time, ensuring the integrity of the coils is maintained. Robotics further facilitates precision in coil handling, minimizing errors and ensuring safety. These innovations not only optimize operations but also bolster compliance with stringent quality standards and regulations. By harnessing these technological advancements, businesses can sustainably boost efficiency, ensure safety, and surpass client expectations.

Conclusion

Steel coil packaging is a crucial aspect of modern industrial operations. Effective methods like stretch wrapping, strapping, and the use of protective materials safeguard coils during transit and storage. Meanwhile, innovations in automation and smart technologies bring future-forward enhancements that optimize efficiency and safety. Through continuous advancements, manufacturers can enjoy improved operational productivity and reduced risks.

Summarize the essential aspects of steel coil packaging, emphasizing its importance in modern industry and the potential benefits of ongoing innovations.