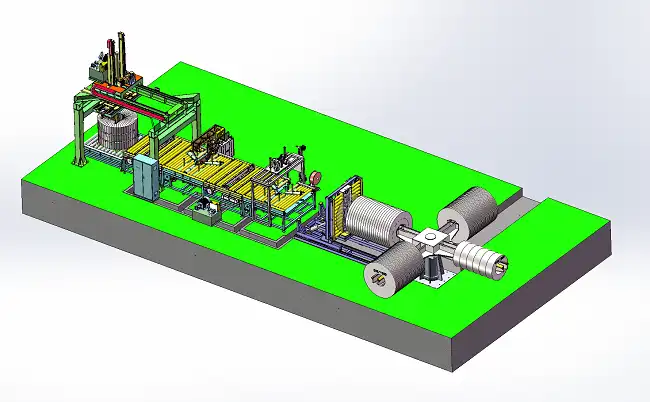

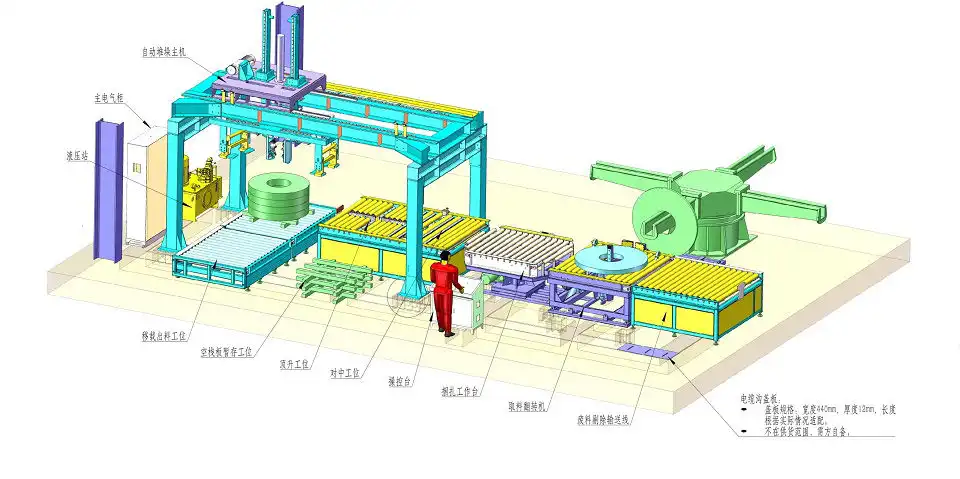

In today's competitive steel industry, maximizing efficiency and reducing costs are crucial for success. One of the most effective ways to achieve these goals is by investing in an automated coil packing line. An automated coil packing line streamlines the process of packaging steel coils, resulting in increased productivity, improved quality control, and reduced labor costs. In this article, we'll explore the benefits of an automated coil packing line and how it can help your steel processing facility maximize efficiency.

Heading 1: Increased Throughput and Productivity

One of the primary advantages of an automated coil packing line is its ability to significantly increase throughput and productivity. Compared to manual packing methods, an automated line can process coils much faster and more consistently. Consider the following benefits:

- High-speed operation: Automated packing lines are designed to operate at high speeds, enabling you to process a larger volume of coils in a shorter amount of time.

- Continuous operation: With an automated line, you can achieve continuous operation with minimal downtime, as the system can run uninterrupted for extended periods.

- Reduced manual intervention: Automated packing lines require minimal manual intervention, allowing your operators to focus on other high-value tasks while the machine handles the packing process.

Heading 2: Improved Quality Control and Consistency

Automated coil packing lines offer superior quality control and consistency compared to manual packing methods. By eliminating human error and variability, an automated line ensures that every coil is packed to the same high standard. Consider the following benefits:

- Precise packaging: Automated lines use advanced sensors and control systems to ensure that each coil is packaged with the correct amount of material and tension, resulting in a tight and secure package.

- Consistent packaging quality: With an automated line, you can achieve consistent packaging quality across all coils, regardless of operator skill level or fatigue.

- Reduced damage and waste: Automated packing lines minimize the risk of damage to the coils during the packaging process, reducing waste and improving overall product quality.

Heading 3: Enhanced Safety and Ergonomics

Safety and ergonomics are critical considerations in any steel processing facility. An automated coil packing line can significantly enhance both aspects, creating a safer and more comfortable work environment for your operators. Consider the following benefits:

- Reduced manual handling: Automated lines minimize the need for operators to manually handle heavy coils, reducing the risk of strain, fatigue, and injury.

- Ergonomic design: Automated packing lines are designed with ergonomics in mind, featuring user-friendly controls and interfaces that reduce operator fatigue and discomfort.

- Safety features: Automated lines incorporate various safety features, such as emergency stop buttons, safety interlocks, and guarding, to protect operators from potential hazards.

Heading 4: Flexible Packaging Options and Customization

An automated coil packing line offers flexibility and customization options to meet your specific packaging requirements. Whether you need to pack coils of different sizes, use various packaging materials, or apply custom labeling, an automated line can adapt to your needs. Consider the following benefits:

- Accommodates various coil sizes: Automated lines can be configured to handle a wide range of coil sizes and dimensions, allowing you to process different products with a single line.

- Supports different packaging materials: Automated lines can work with various packaging materials, such as paper, plastic film, or VCI (Volatile Corrosion Inhibitor) materials, depending on your specific requirements.

- Customizable packaging patterns: Automated lines offer customizable packaging patterns, such as eye-to-sky, eye-to-wall, or eye-to-eye, to suit your customers' preferences or transportation needs.

Heading 5: Seamless Integration with Existing Systems

An automated coil packing line can be seamlessly integrated with your existing systems and processes, ensuring a smooth transition and minimal disruption to your operations. Consider the following aspects:

- Compatible with upstream and downstream equipment: Automated lines can be designed to integrate with your existing coil production, handling, and storage equipment, creating a cohesive and efficient workflow.

- Integration with plant management systems: Automated lines can be connected to your plant management or ERP systems, enabling real-time data exchange, production monitoring, and inventory tracking.

- Modular and scalable design: Automated lines often feature a modular and scalable design, allowing you to easily expand or modify the system as your production needs change over time.

Heading 6: Reduced Labor Costs and Increased Efficiency

One of the most significant benefits of an automated coil packing line is its potential to reduce labor costs while increasing overall efficiency. By automating the packing process, you can minimize the need for manual labor and redeploy your workforce to more value-added tasks. Consider the following advantages:

- Lower direct labor costs: Automated lines require fewer operators than manual packing methods, reducing your direct labor costs associated with the packing process.

- Increased productivity per operator: With an automated line, each operator can oversee the packing of a larger number of coils, increasing their productivity and contribution to the overall output.

- Reallocation of labor resources: By reducing the labor requirements for packing, you can reassign your operators to other critical tasks, such as quality control, maintenance, or process improvement initiatives.

Heading 7: Real-Time Monitoring and Data Analytics

An automated coil packing line equipped with real-time monitoring and data analytics capabilities can provide valuable insights into your packing process, enabling you to make data-driven decisions and continuously improve your operations. Consider the following benefits:

- Real-time performance tracking: Automated lines can collect and display real-time data on key performance indicators (KPIs), such as throughput, cycle times, and equipment utilization, allowing you to monitor and optimize the packing process.

- Data-driven decision making: By analyzing the data collected from the automated line, you can identify bottlenecks, inefficiencies, and improvement opportunities, enabling you to make informed decisions and implement targeted solutions.

- Predictive maintenance: Advanced automated lines can use data analytics to predict when maintenance or repairs may be needed, allowing you to schedule proactive maintenance and avoid unplanned downtime.

Heading 8: Reduced Energy Consumption and Environmental Impact

An automated coil packing line can help reduce your facility's energy consumption and environmental impact, contributing to a more sustainable and cost-effective operation. Consider the following aspects:

- Energy-efficient components: Automated lines often feature energy-efficient components, such as motors, drives, and pneumatic systems, which consume less power than older, less efficient equipment.

- Optimized packaging material usage: Automated lines can optimize the use of packaging materials, reducing waste and minimizing the environmental impact associated with material production and disposal.

- Reduced carbon footprint: By increasing efficiency and reducing energy consumption, an automated coil packing line can help lower your facility's overall carbon footprint, supporting your sustainability goals.

Heading 9: Enhanced Customer Satisfaction and Competitiveness

Investing in an automated coil packing line can ultimately lead to enhanced customer satisfaction and increased competitiveness in the market. By delivering consistently high-quality packaged coils and improving your responsiveness to customer demands, you can differentiate your business from competitors. Consider the following benefits:

- Improved product quality and consistency: Automated lines ensure that every coil is packed to the same high standard, meeting or exceeding your customers' expectations for product quality and protection.

- Faster order fulfillment: With increased throughput and efficiency, an automated line enables you to process and ship orders more quickly, improving your responsiveness to customer demands and reducing lead times.

- Enhanced brand reputation: By consistently delivering high-quality packaged coils and demonstrating a commitment to efficiency and innovation, you can enhance your brand reputation and attract new customers.

Heading 10: Return on Investment and Long-Term Benefits

While investing in an automated coil packing line requires an initial capital expenditure, the long-term benefits and return on investment (ROI) can be substantial. Consider the following factors:

- Reduced operating costs: The labor, energy, and material savings achieved through an automated line can significantly reduce your ongoing operating costs, contributing to a stronger bottom line.

- Increased production capacity: An automated line's higher throughput and efficiency can help increase your overall production capacity, enabling you to take on more orders and grow your business.

- Future-proofing your operations: Investing in an automated coil packing line positions your facility for the future, ensuring that you can adapt to evolving industry demands and maintain a competitive edge in the market.

Conclusion

An automated coil packing line is a powerful tool for maximizing efficiency, reducing costs, and improving product quality in your steel processing facility. By increasing throughput, enhancing quality control, improving safety and ergonomics, offering flexible packaging options, seamlessly integrating with existing systems, reducing labor costs, providing real-time monitoring and data analytics, reducing energy consumption and environmental impact, and enhancing customer satisfaction and competitiveness, an automated coil packing line delivers a wide range of benefits that can transform your packing process and drive long-term success.

When considering an investment in an automated coil packing line, it is essential to carefully evaluate your specific needs, production goals, and budget. By partnering with an experienced and reputable equipment supplier and thoroughly assessing the potential ROI, you can make an informed decision that will position your facility for success in the competitive steel industry.

Ultimately, an automated coil packing line is not just an investment in equipment; it is an investment in your facility's future, enabling you to streamline your operations, adapt to changing market demands, and continuously improve your performance. By embracing the power of automation and innovation, you can unlock new levels of efficiency, quality, and competitiveness, setting your steel processing facility apart from the competition and ensuring long-term growth and success.