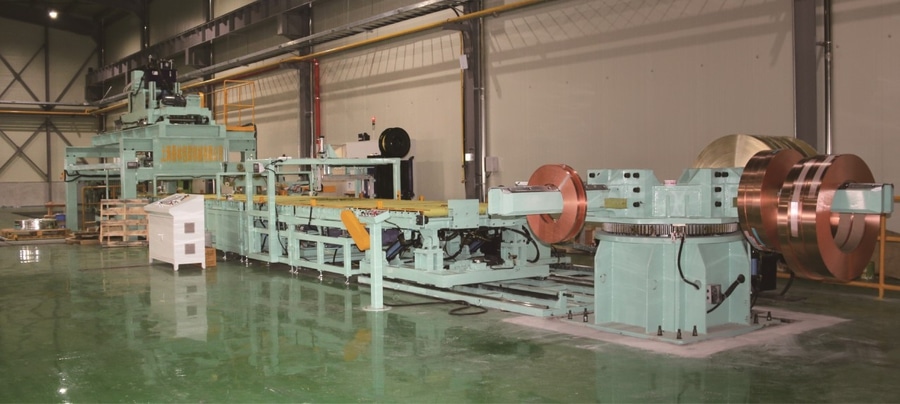

In the rapidly evolving steel industry, manufacturers are constantly seeking ways to improve efficiency, reduce costs, and enhance product quality. One area that has seen significant advancements in recent years is the packaging of steel coils, particularly slit coils. Slit coil packing lines represent the future of steel coil packaging, offering a range of benefits that traditional packaging methods simply cannot match. In this article, we'll explore the advantages of slit coil packing lines and how they are revolutionizing the steel industry.

Heading 1: Increased Efficiency and Productivity

One of the primary advantages of a slit coil packing line is its ability to significantly increase efficiency and productivity in the packaging process. Compared to manual packaging methods, a slit coil packing line can process coils at a much faster rate, reducing cycle times and increasing overall output. This is achieved through several key features:

- Automated material handling: Slit coil packing lines utilize automated conveyors, lifters, and positioning systems to move coils through the packaging process quickly and efficiently, minimizing manual handling and reducing the risk of damage.

- High-speed wrapping: Advanced wrapping machines can apply protective materials, such as paper or plastic film, to the coils at a rapid pace, ensuring a tight and secure wrap that protects the coils during transportation and storage.

- Precise tension control: Slit coil packing lines incorporate sophisticated tension control systems that maintain consistent tension throughout the wrapping process, resulting in a uniform and stable package.

Heading 2: Enhanced Product Protection and Quality

Another significant benefit of slit coil packing lines is their ability to provide enhanced product protection and maintain the highest levels of quality. Steel coils, particularly slit coils, are susceptible to damage during handling and transportation, which can lead to costly rejections and customer complaints. Slit coil packing lines address these issues through several innovative features:

- Customizable packaging materials: Slit coil packing lines can accommodate a wide range of packaging materials, including VCI (Volatile Corrosion Inhibitor) paper, plastic film, and specialized coatings, allowing manufacturers to choose the best option for their specific product and environmental conditions.

- Precise edge protection: Slit coils have sensitive edges that require extra protection during packaging. Slit coil packing lines feature dedicated edge protection systems that apply foam, paper, or plastic guards to the coil edges, preventing damage and ensuring a clean, burr-free surface.

- Climate-controlled packaging: Some slit coil packing lines incorporate climate-controlled packaging systems that maintain a stable environment within the package, protecting the coils from moisture, dust, and other contaminants that can lead to corrosion or quality issues.

Heading 3: Flexibility and Adaptability

Steel manufacturers often produce a wide range of coil sizes and specifications to meet the diverse needs of their customers. Slit coil packing lines offer unparalleled flexibility and adaptability, allowing manufacturers to quickly and easily adjust the packaging process to accommodate different coil sizes, materials, and customer requirements.

- Adjustable machine settings: Slit coil packing lines feature user-friendly control systems that allow operators to quickly adjust machine settings, such as wrapping tension, overlap, and speed, to optimize the packaging process for each coil.

- Quick changeover: When switching between different coil sizes or packaging materials, slit coil packing lines offer fast and efficient changeover procedures, minimizing downtime and maximizing productivity.

- Modular design: Many slit coil packing lines feature a modular design that allows manufacturers to easily add, remove, or modify components as their needs change, ensuring that the line can adapt to future production requirements.

Heading 4: Improved Safety and Ergonomics

Safety and ergonomics are critical considerations in any steel processing facility, and slit coil packing lines offer significant improvements in both areas. By automating the packaging process and reducing manual handling, slit coil packing lines create a safer and more comfortable work environment for operators.

- Reduced manual handling: Slit coil packing lines minimize the need for operators to manually lift, carry, or position heavy coils, reducing the risk of strains, sprains, and other musculoskeletal injuries.

- Ergonomic workstations: Operators of slit coil packing lines benefit from ergonomically designed workstations that provide a comfortable and efficient working environment, with features such as adjustable height controls, intuitive touchscreens, and easy-to-reach emergency stop buttons.

- Improved safety features: Slit coil packing lines incorporate advanced safety features, such as light curtains, safety interlocks, and guarding systems, that prevent accidents and protect operators from potential hazards.

Heading 5: Integration with Industry 4.0 Technologies

As the steel industry embraces the principles of Industry 4.0, slit coil packing lines are designed to seamlessly integrate with advanced technologies that enable smart, data-driven manufacturing. By incorporating sensors, automation, and data analytics, slit coil packing lines provide valuable insights into the packaging process, allowing manufacturers to optimize performance, reduce waste, and improve quality control.

- Real-time monitoring: Slit coil packing lines can be equipped with sensors and monitoring systems that provide real-time data on machine performance, coil specifications, and packaging quality, enabling operators to quickly identify and address any issues that arise.

- Predictive maintenance: By analyzing data from the packing line, manufacturers can predict when maintenance or repairs will be needed, allowing them to schedule downtime proactively and avoid unexpected breakdowns that can disrupt production.

- Integration with ERP and MES: Slit coil packing lines can be seamlessly integrated with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES), enabling manufacturers to track coils throughout the production process, from raw material to finished product, and optimize inventory management and scheduling.

Heading 6: Reduced Labor Costs and Increased Profitability

Investing in a slit coil packing line can significantly reduce labor costs and increase profitability for steel manufacturers. By automating the packaging process, manufacturers can reduce the number of operators required to run the line, while simultaneously increasing output and efficiency.

- Fewer operators required: Slit coil packing lines require fewer operators compared to manual packaging methods, as the automated systems handle the majority of the work. This allows manufacturers to redeploy their workforce to other value-added tasks, such as quality control or machine maintenance.

- Increased throughput: With a slit coil packing line, manufacturers can achieve higher throughput rates, as the automated systems can process coils faster and more consistently than manual methods. This increased output can help manufacturers meet customer demand more efficiently and take on additional orders.

- Reduced packaging costs: Slit coil packing lines optimize the use of packaging materials, reducing waste and minimizing the cost per packaged coil. Additionally, the improved package quality and protection provided by these lines can help reduce the incidence of damaged or rejected coils, further reducing costs associated with rework or replacements.

Heading 7: Improved Sustainability and Environmental Responsibility

As the world becomes increasingly focused on sustainability and environmental responsibility, steel manufacturers are under pressure to adopt eco-friendly practices. Slit coil packing lines can help manufacturers meet these challenges by reducing waste, minimizing energy consumption, and promoting the use of sustainable packaging materials.

- Reduced packaging waste: Slit coil packing lines optimize the use of packaging materials, reducing the amount of waste generated during the packaging process. This not only helps manufacturers reduce their environmental footprint but also lowers disposal costs.

- Energy-efficient operation: Modern slit coil packing lines are designed with energy efficiency in mind, incorporating features such as regenerative braking systems, energy-efficient motors, and optimized pneumatic systems that minimize energy consumption and reduce the line's carbon footprint.

- Sustainable packaging materials: Slit coil packing lines can accommodate a wide range of eco-friendly packaging materials, such as recyclable paper, biodegradable plastics, and materials made from renewable resources. By adopting these sustainable packaging options, manufacturers can demonstrate their commitment to environmental responsibility and meet the growing demand for green products.

Heading 8: Enhanced Customer Satisfaction and Competitiveness

Ultimately, investing in a slit coil packing line can help steel manufacturers enhance customer satisfaction and improve their competitiveness in the market. By providing consistently high-quality packaged coils, meeting delivery deadlines, and offering customizable packaging options, manufacturers can differentiate themselves from competitors and build strong, long-lasting relationships with their customers.

- Consistent quality: Slit coil packing lines ensure that every coil is packaged to the same high standard, with precise edge protection, secure wrapping, and optimal material usage. This consistency in quality helps manufacturers build a reputation for reliability and attention to detail, which can lead to increased customer loyalty and referrals.

- Faster order fulfillment: With the increased efficiency and productivity provided by a slit coil packing line, manufacturers can process and ship orders more quickly, reducing lead times and improving responsiveness to customer needs. This can be a significant competitive advantage, particularly in time-sensitive industries or when dealing with customers who require just-in-time delivery.

- Customizable packaging: Slit coil packing lines offer a high degree of flexibility and customization, allowing manufacturers to tailor their packaging to meet specific customer requirements. This can include custom labeling, specialized packaging materials, or unique wrapping patterns that help customers easily identify and handle the coils upon receipt.

Heading 9: Rapid Return on Investment and Long-Term Value

While investing in a slit coil packing line requires an initial capital outlay, the long-term benefits and return on investment (ROI) can be substantial. Manufacturers who adopt this technology often see a rapid payback period, followed by ongoing cost savings and increased profitability.

- Reduced operating costs: The labor, material, and energy savings achieved through a slit coil packing line can significantly reduce a manufacturer's operating costs over time. These savings can be reinvested into the business, funding further improvements or expansion.

- Increased production capacity: With a slit coil packing line, manufacturers can process more coils in less time, effectively increasing their production capacity without the need for additional labor or floor space. This increased capacity can help manufacturers take on new customers, expand into new markets, or simply improve their bottom line.

- Future-proofing the business: Investing in a slit coil packing line positions manufacturers for long-term success by ensuring they have the technology and capabilities needed to meet evolving customer demands and industry standards. As the steel industry continues to embrace automation and digitalization, manufacturers with advanced packing lines will be well-positioned to adapt and thrive.

Heading 10: Choosing the Right Slit Coil Packing Line

When considering an investment in a slit coil packing line, it is essential for manufacturers to carefully evaluate their specific needs, production goals, and budget. Not all packing lines are created equal, and selecting the right equipment supplier and configuration can make a significant difference in the line's performance, reliability, and long-term value.

- Assess production requirements: Manufacturers should carefully assess their current and future production requirements, including coil sizes, specifications, and throughput targets. This information will help guide the selection of a packing line with the appropriate capacity, flexibility, and features.

- Evaluate equipment suppliers: It is crucial to partner with a reputable and experienced equipment supplier who can provide a high-quality slit coil packing line, along with comprehensive technical support, training, and after-sales service. Manufacturers should research potential suppliers, visit reference sites, and attend industry trade shows to gather information and compare options.

- Consider total cost of ownership: When evaluating the cost of a slit coil packing line, manufacturers should consider the total cost of ownership, including not only the initial capital investment but also ongoing operating, maintenance, and energy costs. A line with a higher upfront cost may offer better long-term value through reduced operating expenses and increased reliability.

Conclusion

Slit coil packing lines represent the future of steel coil packaging, offering a wide range of benefits that can help manufacturers improve efficiency, reduce costs, enhance product quality, and increase customer satisfaction. By automating the packaging process, integrating with advanced technologies, and promoting sustainable practices, slit coil packing lines enable manufacturers to stay ahead of the curve in an increasingly competitive industry.

As steel manufacturers look to invest in new packaging technologies, they should carefully consider the advantages of slit coil packing lines and evaluate their specific needs and requirements. By partnering with a trusted equipment supplier and selecting a packing line that aligns with their production goals and budget, manufacturers can unlock the full potential of this innovative technology and position themselves for long-term success in the global steel market.

Embracing the future of steel coil packaging with a slit coil packing line is not just a smart business decision; it is a strategic investment in a manufacturer's ability to adapt, grow, and thrive in an ever-evolving industry landscape. With the right technology, expertise, and mindset, steel manufacturers can transform their packaging operations into a key competitive advantage, setting the stage for a bright and prosperous future.