The pallet inverter is equipped with the safety device of the 'interlock device'. When the pallet is being pulled, the feeder and the operator's cabinet of the machine must be in the same position. If not, the pallet inverter will not work and the pallet will not be pulled out. The pallet inverter is control by the remote control to ease the operator's operation.

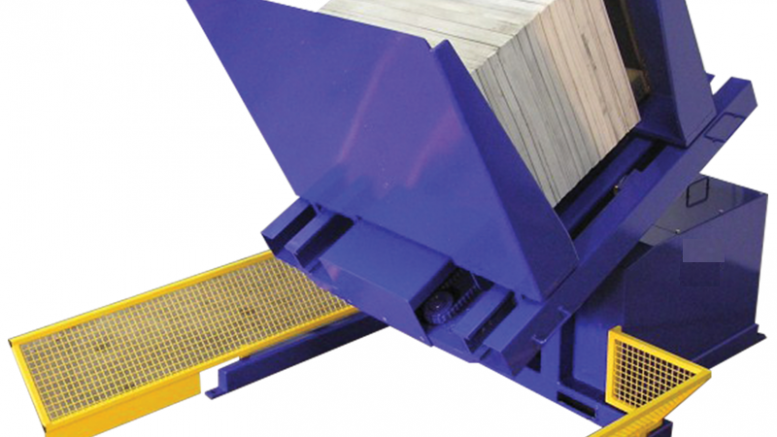

Section 1: The feacture of the pallet inverter

Section 2: The main parts of the machine Section

3: What is a Pallet ch?

Section 4: How much material can be packed onto a pallet?

Takeaway: The fundamental question you must ask yourself when purchasing your pallet inverter is, "what's the maximum weight and weight limit?" If you are unsure about this, don't buy it. 1. Disadvantages

-Cheap

-Transportation of the pallet

-Lack of reliability

2. Benefits

-Pulling the pallet out is easy

-Hands don't face any risks

-Safer for the operator

The pallet inverter is safety for operator is the pallet changing handling. With the pallet inverter, it is no need for the operator to get out of the machine to control the pallet. The pallet inverter and the pallet change is safe. It is also easy to operate. The pallet is being automatically placed and can be changed easily. The pallet inverter is made of the advanced technology.

The pallet inverter is special for the pallet changing opeation.