Packaging challenges? We've all been there. Finding the right coil packing solution can seem overwhelming. But don't worry, we've done the research. Join us, and simplify the search.

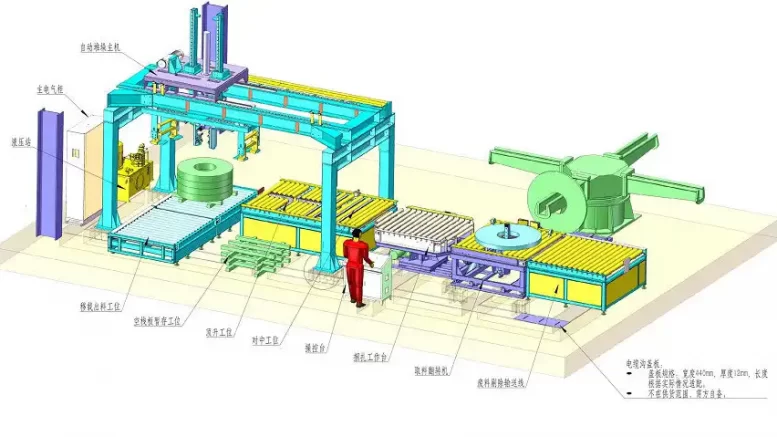

The leading coil packing line manufacturers in the industry provide a range of advanced solutions that cater to diverse needs. Their offerings include high-speed automation, customization options, and state-of-the-art technology to ensure efficiency and reliability in packaging systems for various industries.

Exploring the top manufacturers is just the beginning. Dive into the specifics of leading brands, and see which aligns with your company's goals. These leaders in the industry offer cutting-edge solutions that redefine how coils are packed and shipped.

1. Who are the Leading Coil Packing Line Manufacturers?

In a world where packaging serves as the frontline of operations, finding the right manufacturer is crucial. From product innovation to logistical mastery, the right partner can make all the difference.

To identify the leading coil packing line manufacturers, consider their innovation, reliability, and customer service. Top names like FHOPEPACK are renowned for fully automated solutions, exceptional customization, and global industry trust, consistently setting new standards and meeting diverse packaging needs.

Evaluating Coil Packing Lines

Delving deeper into the leaders in coil packing technology, it is crucial to examine what sets them apart. Understanding their USPs makes it easier to choose the best fit for your business needs.

| Manufacturer | Key Features | Innovations | Customer Support |

|---|---|---|---|

| FHOPEPACK | Total Automation | IoT-enabled systems | 24/7 Global Help |

| XYZ Machine | Customizable Solutions | AI-based operations | Local Assistance |

| ABC Corp | Efficient Production Lines | Green technology | Dedicated Teams |

In my journey through packaging and handling, FHOPEPACK stands out as a company that redefines efficiency and quality. Their automation and Internet of Things-enabled systems are game changers. They allow businesses to cut manual labor and still maintain high standards.

Innovation is not just about the latest technology. It’s also about how it improves overall operations. Each manufacturer is unique. Focusing on core competencies like customer service, technological integration, and environmental responsibility is crucial. By considering these factors, you can make an informed decision that drives your business's operational success.

The right coil packing line manufacturer can transform your production capabilities. It’s about finding that balance between innovation and reliability. As you explore these top manufacturers, consider how their solutions align with your goals for efficiency and growth.

2. What Innovations are Shaping the Coil Packing Industry?

Automation in coil packing is revolutionizing processes, streamlining efficiency and boosting safety standards. This progress tackles challenges faced by manufacturers daily, generating significant interest in the industry.

Innovations like AI-driven technologies and advanced robotics are reshaping coil packing, enhancing productivity, ensuring safety, and reducing human error. Integration of smart sensors gives real-time feedback, making operations more efficient and reliable.

Advanced Technologies Driving Change

The coil packing industry is undergoing a transformation through the introduction of cutting-edge technologies. Automation is at the forefront of this evolution, providing increased efficiency. The integration of robotics in packing lines allows for precise handling and packing, reducing manual errors. Robotics offers unmatched consistency, which is vital in ensuring high quality standards. Adding sensors and AI further enhances functionality by providing real-time data. This data improves accuracy, reduces waste, and ensures that the machinery operates at optimal efficiency. With AI advancements, predictive maintenance becomes possible, reducing downtime. Smart sensors contribute to better energy management, resulting in sustainability. Combining these technologies creates a seamless and intelligent coil packing line that aligns with industrial demands.

This innovation wave is reshaping the coil packing sector significantly. Companies adopting these technologies experience improved production rates, reduced operational costs, and enhanced safety. The technology addresses diverse challenges, such as labor shortages and increasing demand for quality. As a result, businesses find themselves more competitive, capable, and ready to meet evolving market needs.

| Technology | Feature | Impact |

|---|---|---|

| Robotics | Precision handling and control | Enhanced quality consistency and reduced manual labor |

| AI | Predictive maintenance | Lower downtime and improved operational efficiency |

| Smart Sensors | Real-time data feedback and energy management | Increased sustainability and operational accuracy |

3. How is the Market Demand Influencing Coil Packing Line Manufacturers?

Coil packing line manufacturers must adapt to changing market demands. This shift affects productivity and efficiency, creating urgency for adapting new packaging solutions.

Market demand pushes manufacturers toward more sustainable, efficient, and flexible coil packing solutions. As demand increases, so does the necessity for innovations that meet evolving industry standards.

Navigating the Shifting Marketplace

Manufacturers in the coil packing industry face constant pressure to adapt. Market demand drives innovation as clients require more efficient and versatile packing solutions. The steel industry, for example, demands highly reliable and consistent packing lines to ensure seamless delivery of heavy coils. New solutions aim to minimize downtime and enhance throughput. Automation and flexibility in coil packing systems are paramount, especially with increasing customer expectations for quick turnaround times and reduced costs.

Moreover, sustainability is becoming integral to coil packing. Manufacturers adopt eco-friendly materials and energy-efficient technologies to meet global environmental standards. A move towards digitalization supports this trend, facilitating efficient resource management. It's not only about meeting compliance. Manufacturers who embrace these shifts will see improved customer satisfaction and market position.

In this competitive landscape, it's essential to innovate. By staying ahead of technological trends, manufacturers ensure they meet customer needs while optimizing operational efficiency. This strategy leads to maintaining a robust competitive edge.

| Influence | Manufacturer Response | Outcome |

|---|---|---|

| Increased demand | Adoption of flexible solutions | More efficient and effective industrial operations |

| Sustainability | Implementation of green technologies | Enhanced brand value and compliance with regulations |

| Higher standards | Investment in automation and innovation | Better risk management and improved customer satisfaction |

Conclusion

Manufacturers in the coil packing industry must navigate challenges with innovation. Technological trends, such as automation and sustainability, shape the industry's future. Meeting these demands secures competitive advantages in a dynamic marketplace.

Summarize the insights on leading manufacturers, technological trends, and market dynamics in the coil packing industry.