What Are the Key Benefits of Using Coil Wrapping Machines for Packaging?

Struggling with inefficient packaging methods that damage your products? Discover a solution that can revolutionize your packaging process and boost efficiency, while minimizing costs.

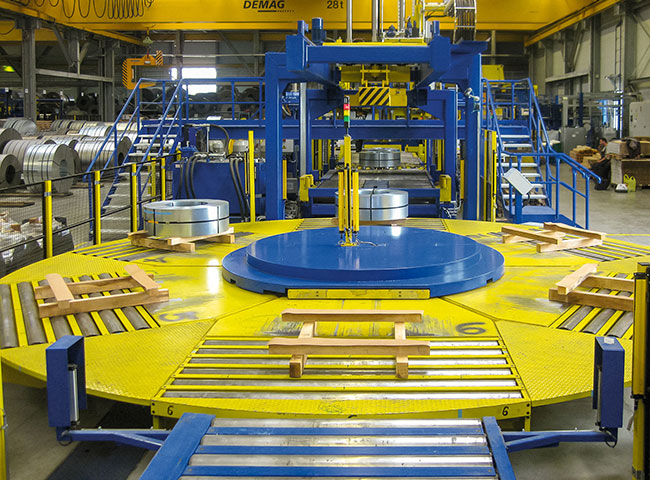

Coil wrapping machines offer unmatched advantages by providing consistent and protective packaging, reducing labor costs, and boosting productivity. These machines enhance product protection, improve packaging speed, and result in fewer damaged goods during transit.

In the fast-paced world of packaging, staying competitive requires innovative solutions. Coil wrapping machines provide a way to safeguard goods while streamlining operations. Let’s explore how this technology can transform your business.

1. How do coil wrapping machines enhance operational efficiency?

Tired of manual packaging draining your resources? Coil wrapping machines offer a way out, automating labor-intensive tasks and increasing throughput.

By automating the wrapping process, coil wrapping machines significantly enhance operational efficiency. They minimize human error, reduce material wastage, and speed up packaging. This ensures consistent and reliable product protection with less downtime and resource allocation.

Streamlining Production Workflow

In my early years working with packaging solutions, I often witnessed companies struggling with production bottlenecks. Manual packaging was labor-intensive and error-prone. Coil wrapping machines address these challenges head-on by integrating seamlessly into production lines. They can handle a range of coil sizes and materials, offering flexibility unmatched by manual methods.

To illustrate, consider a typical workflow comparison:

| Task | Manual Process | Coil Wrapping Machine |

|---|---|---|

| Material Loading | Slow | Fast |

| Consistency | Variable | High |

| Labor Requirements | High | Low |

| Error Rate | Moderate | Low |

The transition to automated wrapping not only reduces human error but also ensures optimal use of packaging materials. For instance, precise tension control reduces damages and material waste. Businesses can reroute labor resources to more specialized tasks, reducing overall costs.

In practical application, this means quicker turnover of orders, fewer packaging-related customer complaints, and boosted profitability—all crucial factors in today's competitive market landscape. As a result, coil wrapping machines don't just wrap your products—they wrap up your operational challenges, allowing for greater focus on core business activities.

2. What are the cost-saving benefits of using coil wrapping machines?

Effective coil packing solutions can enhance productivity and reduce overall operational costs. Discover the financial advantages these machines offer.

Implementing coil wrapping machines in manufacturing processes leads to reduced labor expenses, minimized material waste, and enhanced throughput. These savings contribute to the overall financial efficiency of industrial operations.

Implementing Automation for Cost Efficiency

Coil wrapping machines present numerous cost-saving benefits for manufacturers. These machines reduce manual labor requirements, leading to significant long-term savings on labor costs. By automating the wrapping process, companies also achieve consistent packaging quality, which minimizes material waste and product damage. This consistency enhances the reliability of coil deliveries, reducing expenses related to returns and customer dissatisfaction.

| Cost-Saving Aspect | Details |

|---|---|

| Labor Cost Reduction | Automates wrapping, reducing dependence on manual labor. |

| Material Waste Minimization | Precise wrapping decreases packaging material usage. |

| Enhanced Product Quality | Consistent wrapping leads to fewer damages in transit. |

In my years of experience, I've observed these benefits reflected in improved production metrics. The machines help optimize warehouse space since less material storage is required. This automation streamlines operations, allowing companies to redirect resources towards other revenue-generating activities. These financial advantages are crucial for businesses seeking to remain competitive in today's fast-paced market.

3. What challenges are associated with coil wrapping machines, and how can they be overcome?

Manufacturers may face hurdles when adopting coil wrapping machines. Identifying these challenges is crucial before implementation.

Addressing coil wrapping machine challenges involves proactive maintenance, skilled workforce training, and equipment customization. These solutions minimize disruptions and enhance operational effectiveness.

Identifying and Addressing Operational Hurdles

The introduction of coil wrapping machines is not without its set of challenges. One major concern is the initial capital expenditure, which may strain company budgets. However, viewed as a long-term investment, the returns on efficiency and cost savings can outweigh these upfront costs. Another challenge is the need for skilled operators who can handle the machines competently. By investing in comprehensive training programs, companies can equip their staff with the necessary skills.

| Challenge | Solution |

|---|---|

| High Initial Investment | Long-term cost-benefit analysis highlights efficiency gains. |

| Operator Skillset | Frequent training sessions ensure workforce competence. |

| Machine Downtime | Scheduled maintenance reduces potential operational disruptions. |

Initial setup and maintenance can also pose issues, potentially leading to unplanned downtime. To mitigate this, adopting a scheduled maintenance routine ensures that any issues are addressed proactively, keeping the machines running efficiently. In my career, I have found that partnering with manufacturers for support and customization opportunities greatly assists in overcoming machine-specific hurdles, ensuring seamless integration into existing systems.

Conclusion

This article highlights the efficiency increases and cost savings achieved through coil wrapping machines, while addressing potential challenges with practical solutions. Together, these insights provide a comprehensive understanding of how these machines can revolutionize packaging operations.

This article highlights the efficiency increases and cost savings achieved through coil wrapping machines, while addressing potential challenges with practical solutions. Together, these insights provide a comprehensive understanding of how these machines can revolutionize packaging operations.