The packaging industry is evolving rapidly, and coil wrapping machines are at the forefront of this transformation. With advancements in automation, precision, and sustainability, these machines are revolutionizing how industries handle heavy steel coils. If you're looking to stay ahead, understanding these innovations is crucial.

The latest innovations in coil wrapping machine technology include fully automated systems, IoT integration for real-time monitoring, and eco-friendly materials. These advancements enhance efficiency, reduce labor costs, and ensure damage-free delivery, making them indispensable for modern manufacturing.

As someone who has spent decades in the packaging machinery industry, I’ve witnessed firsthand how these innovations have reshaped the landscape. Let’s dive deeper into how automation, IoT, and sustainability are transforming coil wrapping machines and why they matter to professionals like David.

1. How Has Automation Transformed Coil Wrapping Machines?

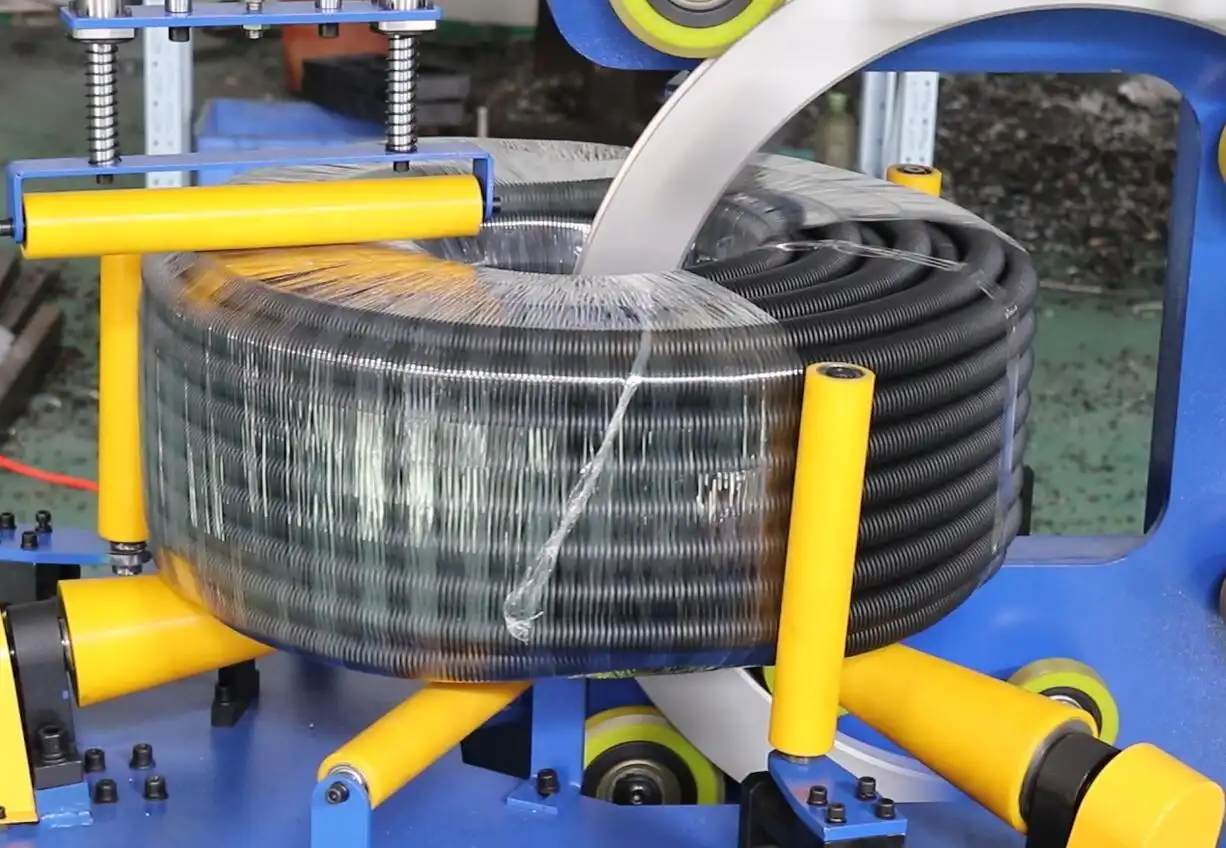

Automation has become a game-changer in the packaging industry, and coil wrapping machines are no exception. Imagine a machine that can handle heavy steel coils with precision, consistency, and minimal human intervention. That’s the power of automation.

Automation in coil wrapping machines has led to faster operation speeds, improved wrapping consistency, and reduced labor costs. These machines now feature programmable logic controllers (PLCs) and robotic arms, ensuring seamless integration into production lines.

The Role of PLCs and Robotics in Automation

Programmable Logic Controllers (PLCs) and robotics are the backbone of modern automated coil wrapping machines. PLCs allow for precise control over the wrapping process, ensuring that each coil is wrapped to exact specifications. Robotics, on the other hand, handle tasks like loading and unloading coils, reducing the need for manual labor.

Here’s a breakdown of how these technologies compare:

| Feature | Traditional Machines | Automated Machines |

|---|---|---|

| Operation Speed | Moderate | High |

| Consistency | Variable | High |

| Labor Dependency | High | Low |

| Integration with IoT | Not Available | Available |

| Maintenance Costs | Moderate | Low |

Automation not only improves efficiency but also enhances safety. Heavy steel coils can be dangerous to handle manually, but automated systems minimize human interaction, reducing the risk of accidents. For professionals like David, this means fewer workplace injuries and lower insurance costs.

Moreover, automated coil wrapping machines are highly customizable. They can be programmed to handle coils of different sizes and weights, making them versatile for various industries. Whether it’s automotive or construction, these machines adapt to specific needs, ensuring optimal performance.

2. IoT Integration: The Future of Coil Wrapping Machines

The Internet of Things (IoT) is transforming industries, and coil wrapping machines are no exception. IoT-enabled machines offer real-time monitoring, predictive maintenance, and data-driven insights, making them smarter and more efficient.

IoT integration in coil wrapping machines allows for real-time monitoring of machine performance, predictive maintenance alerts, and data analytics. This reduces downtime, improves efficiency, and ensures consistent quality.

How IoT Enhances Machine Performance

IoT-enabled coil wrapping machines are equipped with sensors that collect data on various parameters like temperature, vibration, and power consumption. This data is transmitted to a central system where it’s analyzed to provide actionable insights.

Here’s how IoT benefits coil wrapping machines:

- Real-Time Monitoring: Operators can monitor machine performance in real-time, allowing for immediate adjustments if something goes wrong.

- Predictive Maintenance: Sensors detect anomalies that could indicate potential failures, enabling maintenance before a breakdown occurs.

- Data Analytics: Collected data is analyzed to identify trends and optimize machine performance over time.

For professionals like David, IoT integration means fewer unexpected downtimes and more efficient operations. It also provides valuable data that can be used to improve processes and reduce costs.

3. Sustainability: The New Frontier in Coil Wrapping Technology

Sustainability is no longer just a buzzword; it’s a necessity. The packaging industry is under increasing pressure to reduce its environmental footprint, and coil wrapping machines are rising to the challenge.

Sustainable innovations in coil wrapping machines include the use of eco-friendly materials, energy-efficient designs, and recyclable components. These advancements not only reduce environmental impact but also lower operational costs.

Eco-Friendly Materials and Energy Efficiency

Modern coil wrapping machines are designed with sustainability in mind. They use materials that are recyclable and biodegradable, reducing waste. Additionally, energy-efficient motors and components minimize power consumption, lowering the carbon footprint.

Here’s a comparison of traditional vs. sustainable coil wrapping machines:

| Feature | Traditional Machines | Sustainable Machines |

|---|---|---|

| Material Recyclability | Low | High |

| Energy Consumption | High | Low |

| Waste Generation | High | Low |

| Operational Costs | High | Low |

For industries like automotive and construction, where sustainability is increasingly important, these innovations are a game-changer. They not only help companies meet regulatory requirements but also appeal to environmentally conscious consumers.

Conclusion

The latest innovations in coil wrapping machine technology—automation, IoT integration, and sustainability—are transforming the packaging industry. These advancements offer numerous benefits, from improved efficiency and safety to reduced environmental impact. For professionals like David, staying updated with these trends is essential to remain competitive in a rapidly evolving industry.

At FHOPEPACK, we’re committed to providing cutting-edge solutions that meet the needs of modern manufacturing. Whether you’re looking to automate your packaging process or adopt sustainable practices, we’re here to help. Explore our range of coil wrapping machines and discover how we can revolutionize your operations.