The decision to invest in a coil wrapping machine often stems from the pursuit of efficiency, precision, and cost savings in packaging processes. However, before making such a significant purchase, understanding the return on investment (ROI) is crucial. This calculation not only reflects the financial benefits but also provides insights into operational improvements and long-term value. With the right machine, businesses can streamline workflows, reduce waste, and improve product handling, all of which contribute to a higher ROI.

In today’s competitive market, every investment must justify itself. A coil wrapping machine, while potentially transformative, represents a substantial upfront cost. Companies must evaluate not just the initial price but also the ongoing advantages it offers. From reducing manual labor to enhancing product protection, the benefits can be significant—but only when carefully analyzed in alignment with business goals.

When considering ROI, it’s important to look beyond the numbers. Operational efficiency, reduced downtime, and improved customer satisfaction are intangible factors that play a significant role. This article explores the expected ROI of a coil wrapping machine investment, offering a detailed breakdown of key considerations and answering common questions that arise during the decision-making process.

Table of Contents

- How Does a Coil Wrapping Machine Impact Operational Costs?

- 1.1 Reduced Labor Costs

- 1.2 Lower Material Waste

- 1.3 Increased Packaging Speed

- What Are the Long-Term Benefits of Automation?

- 2.1 Enhanced Consistency in Packaging

- 2.2 Improved Equipment Lifespan

- 2.3 Scalable Solutions for Growing Businesses

- How to Choose the Right Coil Wrapping Machine?

- 3.1 Assessing Machine Features and Specifications

- 3.2 Understanding Maintenance and Support Requirements

- 3.3 Evaluating Cost vs. Value

- What Metrics Should You Use to Measure ROI?

- 4.1 Tracking Efficiency Gains

- 4.2 Calculating Cost Savings Over Time

- 4.3 Incorporating Customer Satisfaction Metrics

1. How Does a Coil Wrapping Machine Impact Operational Costs?

1.1 Reduced Labor Costs

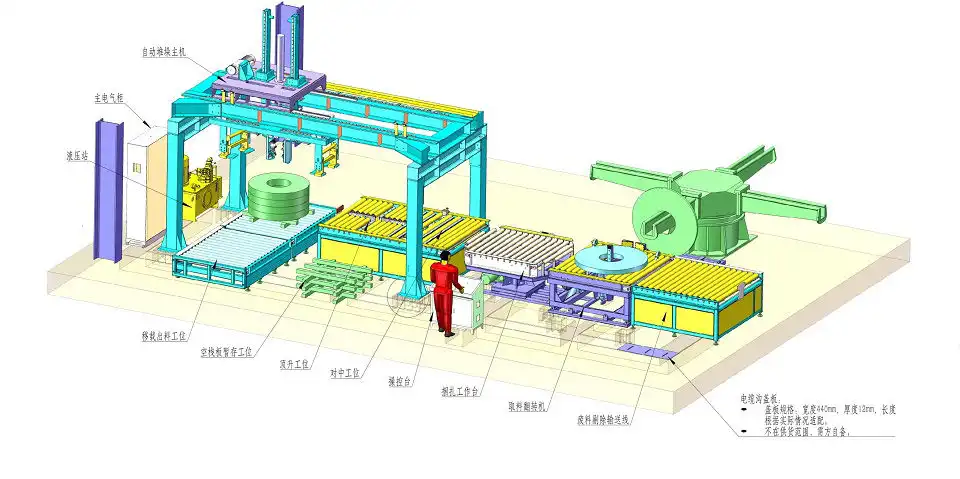

One of the most immediate impacts of a coil wrapping machine is the significant reduction in labor costs. Traditionally, manual wrapping processes require multiple workers, consuming both time and energy. A single machine can replace the need for several employees while completing the task faster and with greater precision. This shift not only cuts expenses but also allows businesses to allocate human resources to more strategic tasks.

For instance, a manufacturing company that previously needed five workers to package coils manually can often accomplish the same output with just one operator managing the machine. Over time, these savings in payroll costs can offset the initial investment, making the machine a cost-effective solution.

1.2 Lower Material Waste

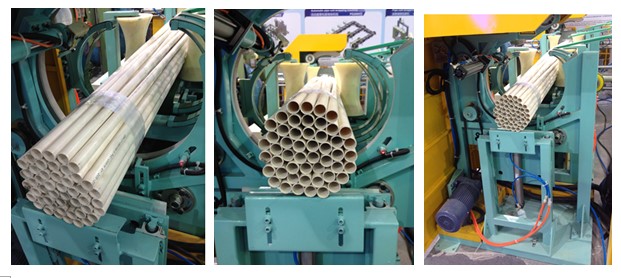

Manual wrapping is prone to inconsistencies, leading to excessive use of materials like stretch film or other packaging components. A coil wrapping machine, on the other hand, is designed for precision. It applies the exact amount of material needed, reducing waste and ensuring uniformity across all packaged products.

The reduction in material waste not only saves money but also aligns with sustainability goals. Companies can improve their environmental footprint while optimizing costs, a dual benefit that resonates with both stakeholders and customers.

1.3 Increased Packaging Speed

Speed is a critical factor in meeting production deadlines and maintaining customer satisfaction. Manual processes are not only slower but also leave room for errors that can delay shipments. A coil wrapping machine eliminates these bottlenecks by performing tasks at a consistent and rapid pace.

For example, some machines can wrap dozens of coils per hour, compared to the manual process, which might only handle a fraction of that number. This boost in efficiency allows companies to scale their operations and meet growing demands without compromising on quality.

2. What Are the Long-Term Benefits of Automation?

2.1 Enhanced Consistency in Packaging

Automation brings a level of consistency that manual processes simply cannot match. A coil wrapping machine ensures that every package is wrapped with the same tension, alignment, and coverage. This uniformity enhances the protection of the product during storage and shipping, reducing the risk of damage.

For businesses, consistent packaging also boosts brand reputation. Customers and clients appreciate well-packaged products that arrive in pristine condition. Furthermore, consistency minimizes returns or complaints, helping businesses maintain a competitive edge in the market.

2.2 Improved Equipment Lifespan

Investing in high-quality coil wrapping machines not only delivers immediate benefits but also extends the lifespan of your packaging infrastructure. With proper maintenance, these machines can operate efficiently for years, reducing the need for frequent replacements.

Unlike manual processes, which are prone to human error and wear-and-tear on materials, automated systems reduce strain on components. This prolongs the machine’s reliability and ensures a better return on the initial investment. Many manufacturers also offer warranties and service packages, further increasing the longevity of the equipment.

![Featured Image][] <!-- Placeholder image for visual reference -->

2.3 Scalable Solutions for Growing Businesses

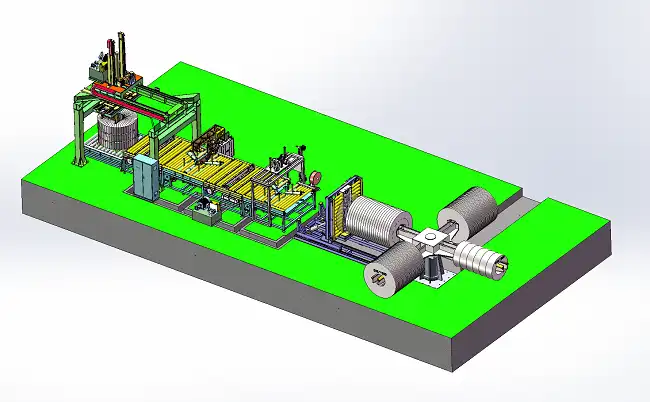

As businesses grow, packaging needs evolve. Automation provides scalable solutions that can adapt to increased production demands. Many coil wrapping machines offer modular designs or customizable features, allowing businesses to expand their operations without requiring entirely new systems.

For instance, if production volume doubles, an automated machine can often handle the increased workload with minimal adjustments. This scalability ensures that the initial investment continues to pay dividends as the business grows, making it a future-proof solution.

3. How to Choose the Right Coil Wrapping Machine?

3.1 Assessing Machine Features and Specifications

Choosing the right coil wrapping machine starts with evaluating its features and specifications. Factors such as wrapping speed, material compatibility, and load capacity are critical. Businesses must identify their specific packaging requirements and ensure the machine meets those needs.

For example, if your operations involve heavy-duty coils, selecting a machine with higher load capacity and robust build quality is essential. Additionally, machines with advanced features like programmable settings or touch-screen controls can offer greater flexibility and ease of use.

3.2 Understanding Maintenance and Support Requirements

When investing in machinery, it’s crucial to consider maintenance needs and the quality of after-sales support. A well-maintained machine operates more efficiently and avoids costly downtime. Look for manufacturers or suppliers that offer comprehensive service packages, including preventative maintenance and quick access to replacement parts.

Moreover, businesses should assess the availability of technical support. Machines with complex systems may require specialized assistance, so reliable customer support can make a significant difference in minimizing disruptions.

![Featured Image][] <!-- Placeholder image for visual reference -->

3.3 Evaluating Cost vs. Value

The upfront cost of a coil wrapping machine is an important consideration, but it’s equally vital to evaluate the long-term value it provides. A cheaper machine may save money initially but could incur higher maintenance and operational costs over time. Conversely, a well-built machine with a higher price tag may deliver better ROI through durability, efficiency, and reduced wastage.

To make an informed decision, businesses should calculate the total cost of ownership (TCO), including purchase price, operating costs, and expected lifespan. Comparing this against projected savings and efficiency gains will help determine the true value of the investment.

4. What Metrics Should You Use to Measure ROI?

4.1 Tracking Efficiency Gains

Efficiency is one of the most critical metrics when measuring the ROI of a coil wrapping machine. By automating the packaging process, businesses can significantly reduce the amount of time spent on each coil. Tracking metrics like wrapping speed (coils per hour) and overall production throughput provides a clear picture of how much time and labor the machine saves.

For instance, if a machine doubles the packaging speed compared to manual wrapping, this efficiency gain translates directly into higher productivity and shorter lead times. Over time, these improvements can lead to substantial financial returns, especially for high-volume operations.

4.2 Calculating Cost Savings Over Time

Another key metric for ROI is the reduction in costs over a set period. Start by comparing pre-automation expenses—such as labor costs, material waste, and manual errors—with the costs associated with running the machine. Include factors like energy consumption, maintenance, and operator wages.

For example, if a business spends $10,000 annually on labor for manual wrapping but reduces that to $2,500 with an automated machine, the $7,500 annual savings can quickly offset the machine’s initial cost. Similarly, savings from reduced material waste and fewer damaged products should also be factored into the equation.

![Featured Image][] <!-- Placeholder image for visual reference -->

4.3 Incorporating Customer Satisfaction Metrics

While financial metrics are important, customer satisfaction should not be overlooked. Well-packaged products that arrive on time and in excellent condition enhance the customer experience. Tracking metrics like customer complaints, product return rates, and delivery feedback can provide indirect insights into the ROI of a coil wrapping machine.

For instance, if product damage during transit decreases due to better packaging, customer trust and loyalty increase. Satisfied customers are more likely to continue purchasing and recommend your business to others, further boosting long-term profitability.

Conclusion

[Claim]: Investing in a coil wrapping machine has the potential to deliver substantial ROI by minimizing costs, increasing efficiency, and enhancing product quality.

The value of automation lies not just in cost savings but also in the transformative impact it has on operations. From reducing labor expenses and material waste to improving consistency and speed, a coil wrapping machine offers a wide range of benefits. For growing businesses, it provides a scalable solution that can adapt to evolving demands while maintaining high-quality output.

When evaluating the ROI, it’s essential to look beyond the initial investment and consider the long-term gains in productivity, reliability, and customer satisfaction. By carefully analyzing metrics like efficiency improvements, cost reductions, and customer feedback, businesses can make an informed decision and maximize their returns.

Ultimately, a coil wrapping machine is more than just a tool; it’s an investment in the future of your business. With the right machine, companies can streamline their packaging processes, reduce waste, and achieve greater profitability, all while delivering exceptional value to their customers.