In the fast-paced world of manufacturing, efficiency is the name of the game. Companies are constantly seeking ways to streamline their processes, reduce costs, and improve output quality. One area where significant gains can be made is in the packing and shipping of coiled materials. This is where automated coil packing lines come into play. These sophisticated systems are designed to optimize the packing process, increase throughput, and minimize manual labor. In this article, we will explore why automated coil packing lines are key to efficiency and how they can help your business stay competitive in today's market.

Heading 1: Boosting Productivity and Reducing Labor Costs

One of the primary reasons why automated coil packing lines are crucial for efficiency is their ability to boost productivity and reduce labor costs. By automating the packing process, these systems can significantly increase the speed and volume of coils being packed, while minimizing the need for manual intervention. Consider the following points:

- High-Speed Operation: Automated coil packing lines are designed to operate at high speeds, often capable of packing multiple coils per minute. This is a stark contrast to manual packing methods, which are much slower and more labor-intensive. By comparing the packing rates of automated systems versus manual methods, it becomes clear that automation offers a substantial productivity advantage.

- Continuous Workflow: Another key benefit of automated coil packing lines is their ability to maintain a continuous workflow. Unlike manual packing, which is subject to breaks, fatigue, and human error, automated systems can operate consistently and without interruption. This translates into higher output, reduced downtime, and improved overall efficiency.

- Labor Optimization: Automated coil packing lines also help optimize labor resources. By reducing the need for manual handling and packing, these systems allow companies to redeploy their workforce to more value-added tasks. This not only reduces labor costs associated with packing but also enables businesses to allocate their human capital more strategically.

When evaluating the impact of automated coil packing lines on productivity and labor costs, it is essential to conduct a comparative analysis. By assessing the performance metrics of automated systems against manual methods, businesses can quantify the potential gains and make informed decisions about investing in automation.

Heading 2: Enhancing Quality Control and Consistency

Another crucial aspect of efficiency is maintaining high levels of quality control and consistency. Automated coil packing lines excel in this area, offering several advantages over manual packing methods. Consider the following points:

- Precision and Accuracy: Automated coil packing lines are equipped with advanced sensors, vision systems, and control mechanisms that ensure precise and accurate packing. These systems can consistently position coils, apply the correct amount of packaging material, and seal the packages with a high degree of precision. By comparing the accuracy levels of automated systems versus manual methods, it becomes evident that automation offers superior quality control.

- Reduced Human Error: Manual packing is inherently prone to human error, which can lead to inconsistencies, damaged products, and customer dissatisfaction. Automated coil packing lines, on the other hand, eliminate the risk of human error by following pre-programmed instructions and maintaining consistent operation. This results in higher quality output and reduced waste.

- Standardized Packaging: Automated coil packing lines also enable businesses to standardize their packaging processes. By using consistent settings, materials, and techniques, these systems ensure that every coil is packed in the same manner, regardless of the operator or shift. This level of standardization is crucial for maintaining brand consistency and meeting customer expectations.

When assessing the impact of automated coil packing lines on quality control and consistency, it is important to consider the potential benefits in terms of reduced defects, improved customer satisfaction, and enhanced brand reputation. By conducting a comparative analysis of automated systems versus manual methods, businesses can determine the extent to which automation can help them achieve their quality goals.

Heading 3: Optimizing Space Utilization and Inventory Management

Style: Comparative Analysis, Practical Guide

Efficiency in manufacturing is not just about speed and quality; it also involves optimizing space utilization and inventory management. Automated coil packing lines can play a significant role in streamlining these aspects of the manufacturing process. Consider the following points:

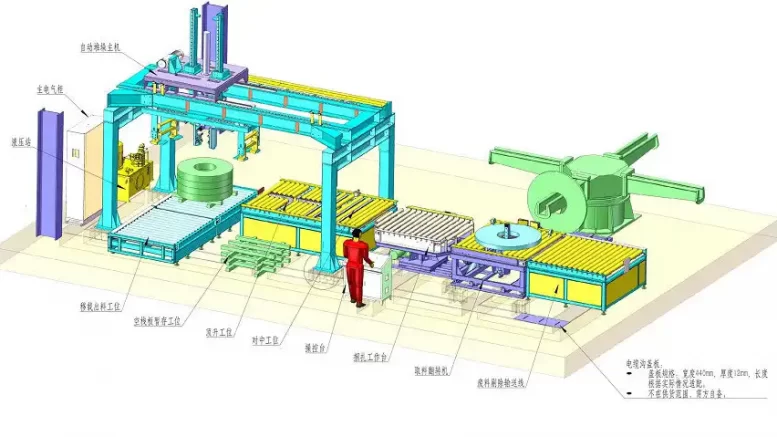

- Compact Footprint: Automated coil packing lines are designed to have a compact footprint, allowing businesses to maximize their floor space. By comparing the space requirements of automated systems versus manual packing stations, it becomes clear that automation offers a more space-efficient solution. This is particularly important for companies operating in limited factory spaces or looking to expand their production capacity without increasing their physical footprint.

- Vertical Integration: Many automated coil packing lines offer vertical integration capabilities, meaning they can be easily integrated with other equipment, such as coil winding machines or conveyor systems. This vertical integration allows for a seamless flow of materials and minimizes the need for manual handling between processes. By comparing the efficiency gains of vertically integrated systems versus standalone manual packing stations, businesses can assess the potential benefits of automation in terms of space utilization and overall process flow.

- Inventory Tracking and Management: Automated coil packing lines can also be equipped with advanced inventory tracking and management systems. These systems can automatically record and update inventory levels as coils are packed and shipped, providing real-time visibility into stock levels and production progress. By comparing the inventory accuracy and traceability of automated systems versus manual methods, businesses can evaluate the potential gains in terms of reduced inventory discrepancies, improved order fulfillment, and better overall supply chain management.

When assessing the impact of automated coil packing lines on space utilization and inventory management, it is important to consider the long-term benefits. By optimizing floor space, streamlining process flow, and enhancing inventory control, businesses can achieve significant cost savings, improve operational efficiency, and position themselves for future growth.

Heading 4: Seamless Integration with Existing Systems and Processes

Another key consideration when implementing automated coil packing lines is their ability to integrate seamlessly with existing systems and processes. A well-designed automation solution should be able to fit into a company's current manufacturing ecosystem without causing significant disruptions or requiring extensive modifications. Consider the following points:

- Compatibility with Existing Equipment: When evaluating automated coil packing lines, it is important to assess their compatibility with existing equipment, such as coil winding machines, material handling systems, and conveyor belts. By comparing the integration capabilities of different automation solutions, businesses can identify the options that offer the most seamless fit with their current setup. This compatibility is crucial for minimizing downtime during installation and ensuring a smooth transition to automated packing.

- Flexibility and Customization: Every manufacturing facility has unique requirements and constraints. Therefore, it is essential to consider the flexibility and customization options offered by different automated coil packing lines. By comparing the adaptability of various systems, businesses can determine which solutions can be tailored to their specific needs. This may include adjustable packing speeds, configurable packaging materials, or modular designs that can be expanded or modified as production requirements change.

- Scalability and Future-Proofing: As businesses grow and evolve, their packing requirements may change. When assessing automated coil packing lines, it is important to consider their scalability and future-proofing potential. By comparing the expandability and upgrade options of different systems, businesses can identify solutions that can grow with their operations. This may involve the ability to add new features, increase packing capacity, or integrate with emerging technologies.

When evaluating the integration capabilities of automated coil packing lines, it is essential to take a holistic view of the manufacturing process. By considering compatibility, flexibility, and scalability, businesses can select automation solutions that not only meet their current needs but also position them for long-term success.

Heading 5: Embracing Automation for Competitive Advantage

In today's competitive manufacturing landscape, embracing automation is no longer a luxury but a necessity. Automated coil packing lines offer a powerful tool for businesses looking to gain a competitive edge. Consider the following points:

- Keeping Pace with Industry Standards: As more and more companies adopt automation in their packing processes, those who rely on manual methods risk falling behind. By comparing the efficiency and output levels of automated systems versus manual packing, businesses can assess the gap between their current operations and industry benchmarks. Investing in automation allows companies to keep pace with evolving industry standards and maintain their competitiveness.

- Responding to Customer Demands: In an era of heightened customer expectations, businesses must be able to respond quickly and efficiently to changing demands. Automated coil packing lines enable companies to adapt their packing processes to meet specific customer requirements, such as custom packaging materials, labeling, or shipping configurations. By comparing the flexibility and responsiveness of automated systems versus manual methods, businesses can evaluate their ability to meet customer needs and differentiate themselves in the market.

- Positioning for Future Growth: Automation is not just about solving today's challenges; it is also about positioning a business for future growth. By investing in automated coil packing lines, companies can lay the foundation for expanded production capacity, improved product quality, and increased operational efficiency. By comparing the long-term growth potential of businesses that embrace automation versus those that rely on manual methods, it becomes clear that automation is a strategic imperative for success in the modern manufacturing landscape.

When assessing the competitive advantages of automated coil packing lines, it is important to take a forward-looking perspective. By considering industry trends, customer expectations, and growth opportunities, businesses can make informed decisions about investing in automation and positioning themselves for long-term success.

Conclusion

In conclusion, automated coil packing lines are a key driver of efficiency in modern manufacturing. By boosting productivity, reducing labor costs, enhancing quality control, optimizing space utilization, and seamlessly integrating with existing systems, these advanced solutions offer a compelling value proposition for businesses looking to streamline their operations and stay competitive.

When evaluating the potential benefits of automated coil packing lines, it is essential to conduct a thorough comparative analysis. By assessing the performance metrics, integration capabilities, and long-term growth potential of automated systems versus manual methods, businesses can make informed decisions about investing in automation.

Ultimately, the decision to implement an automated coil packing line is not just a technical one; it is a strategic choice that can have far-reaching implications for a company's competitiveness, customer satisfaction, and future success. By embracing automation and continuously optimizing their packing processes, businesses can position themselves at the forefront of their industry and set the stage for sustained growth and profitability.

As the manufacturing landscape continues to evolve, those who adapt and innovate will be the ones who thrive. Automated coil packing lines represent a powerful tool in this pursuit of efficiency and excellence. By leveraging these advanced solutions, businesses can unlock new levels of performance, agility, and competitiveness, paving the way for a brighter and more prosperous future.