Coil packing machines for replacing the man power.

The COIL PACKAGING SOLUTION is a complete and integrated coil packaging machine and specialized coil packaging tools, designed to make the packing of welded steel coils and pipe coil, wire coil...easier and more efficient. The coil packaging machine and specialized coil packaging tools provide a packaging solution that is more efficient and thereby reduces labour costs.COIL PACKAGING SOLUTION to replace the man power packaging by machine.

WHAT IS THE DESIGNING PRINCIPLE FOR THE COIL WRAPPING MACHINE

The coil wrapping machine invention addresses this need by providing a ring or wrapping material carrier or dis and method for a wrapping apparatus. The system allows for the replacement of the film dispensing shuttle without the need to remove the track from the eye of the coil, and with minimal downtime for the machine. The system can utilize a ready substitute shuttle, further reducing the downtime necessary to place the machine back into service. coil packing machine

The coil wrapping machine utilizes a heavy-duty, oval-shaped track that guides the film-dispensing shuttle as it travels around the inside of the track. The track features a hinged section or arm that can be lifted to open the track and allow for the lower portion to be inserted into the center of the coil. The track is also adjustable in the vertical plane to accommodate different coil diameters. The track is typically mounted on rails for ease of movement and can also be moved transversely to the direction of the track.

Overall, the invention provides a more efficient and cost-effective method for changing out the film dispensing shuttle and wrapping material in a wrapping apparatus, reducing downtime and labor costs.coil packing machine

The current process for replacing a film roll on a wrapping machine requires the track to be removed from the eye of the coil, the hinged end to be opened, and the shuttle to be positioned at a predetermined location. This procedure is time-consuming and labor-intensive, leading to significant downtime for the machine. To address this issue, there is a need for a system and method for changing out the shuttle without removing the track from the coil. This would ideally involve using a ready substitute shuttle to minimize downtime and labor required for the replacement process.

APPLICATION:

For steel coil packaging:

For steel coil packaging: There are various automatic and semi-automatic packing machines available for steel coil packaging. These machines can provide well-protected packaging for steel strip, slitting coil, alloy coil, and stainless steel. The machinery is specially designed to ensure that the steel coils are packaged securely and protected during transportation.

For steel wire coil packaging: Wire coil packing/wrapping machine is able handle your aluminum wire coil, PI wire coil, PC wire coil, Pre-strand wire coil…by stretch film,paper, pvc… The solution can be vary from your handling operation. coil packing machine

For plastic pipe packing: There are hose coil packing/wrapping machine, pvc pipe wrapping machine for coil packaging from 1kg to 500kg, for coil size OD:200-3000mm, for width50-1500mm…Even there are solution for automatic coiling and pipe packaging. coil packing machine

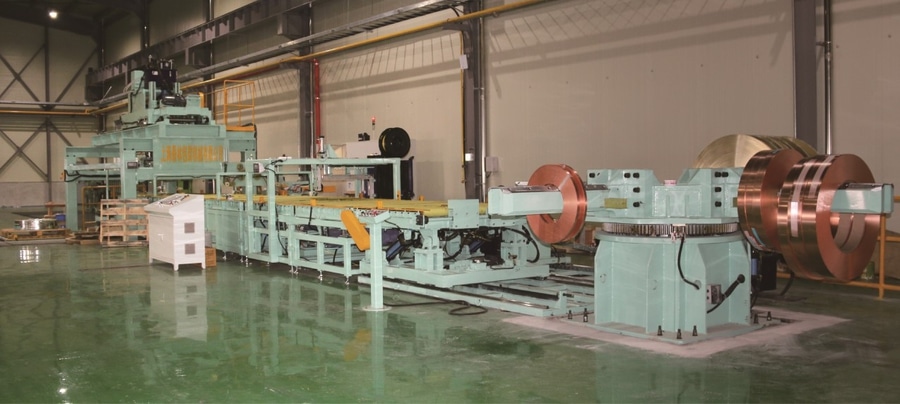

For copper coil packing: Both horizontal coil stretch wrapper and vertical coil wrapper are available for copper strip, coil sheet coil packaging. Automatic packing and stacking line is capable help you reduce the labor cost a lot.

For Tyre packing: Tyre packing/wrapping machine can be designed with different function to meet your need in tyre wrapping, logo tapping, label printing… for your truck tyre, bicycle tyre, small car tyre…

For Bearing packing: Bearing packing machine is a unique designing by shjlpack with eye through wrapping machine. It is able to choose different packing material for different season, different area packaging requirement. It an easy operation bearing packing equipment to increasing your speed.

WHAT CAN BE THE ACCIHEVE BY THE COIL PACKING SOLUTION?

Coil wrapping machine are commonly found in warehouses and manufacturing facilities for the storage and transportation of materials and goods in China. However, it is not so popular in many country. Many Enterprises still using the wrapping tool of manually packaging. By using the wrapping machine to replace the human or changing the semiauto machine into automatic solution, you will be benefited below:

1. Improved working efficiency

Equipped with professional high-speed packaging machine, Shjlpack provides the safest and the most efficient packaging service.

2. Safety

The production line embodies Safety First principle,reliable devices are introduced,uniformly controlled work flow, strictly control the appropriate time of the cutting,heat sealing,closing,packaging process,ensure the safe production.

3. Reduced material waste

Reduced material waste, as the machine can precisely control the amount of wrapping material used.

4. Multifuntion

Options for customization, such as the ability to print branding or product information on the wrapping material.

WHY CHOOSE SHJLPACK

Reasons to Partner with Our Company

-

Global Support and Education:

We go beyond just selling machines. Our expert technicians travel worldwide to provide comprehensive setup, fine-tuning, and hands-on training at your facility. This ensures your team can operate our steel coil wrapping machines effectively from the start, maximizing your investment.

-

Cutting-Edge Technology Integration:

Our equipment is designed to seamlessly connect with advanced packaging automation controls and factory-wide management systems. This integration boosts efficiency, enabling real-time oversight and adjustment of your packaging operations.

-

Tailored Solutions for Your Business:

Understanding that no two operations are alike, we specialize in creating bespoke steel coil wrapping machines. Our designs are customized to align perfectly with your specific operational needs, guaranteeing optimal performance within your unique production environment.

-

Unmatched Industry Experience:

With a 15-year track record and a dedicated team of over 20 engineers, we've built a solid foundation in the industry. This extensive experience translates into machines crafted with unparalleled expertise, reflecting years of industry-leading innovations.

-

Commitment to Excellence and Innovation:

We're dedicated to constant improvement, regularly enhancing our machine designs. This commitment ensures you always have access to the latest technological advancements. Our reputation for delivering reliable, high-performance machines makes us a trusted partner for businesses seeking long-term value.

Convenient Transportation

1) Shjlpack saves customers’ packaging cost,the company sends the goods to the designated place.

2) The packaging workers are all qualified,stable,responsible,and fast.

3) Shjlpack has the professional packing production line,ready stock.

4) Shjlpack has the storehouse,warehouse,pick up service,which can satisfy the customers’ need.

Shjlpack,designs and produces all kinds of industrial packaging for coil package.

Q: What is the production capacity of Shjlpack?

A: Shjlpack is capable of packing 3000 pieces of Coil per day.

Q: what is your export situation?

A: Shjlpack mainly exports to Europe, Southeast Asia, Africa, and America.

|

MODLE |

COIL OD

(mm) |

COIL ID

(mm) |

COIL WIDTH

(mm) |

COIL WEIGHT

(Kg) |

Machine Size

(mm) |

POWER

(KW) |

|

GS200 |

300-600 |

150-300 |

10-200 |

5-100 |

1000X1000X1200 |

1.2 |

|

GS300 |

600-1200 |

300-800 |

50-300 |

10-500 |

1200X1200X1400 |

1.5 |

|

GS400 |

700-1400 |

300-1200 |

50-400 |

100-1000 |

1400X1400X1800 |

2.2 |

|

GS600 |

800-1600 |

400-1400 |

50-600 |

100-1500 |

1600X1600X1900 |

2.5 |

|

GS800 |

1000-1800 |

500-1500 |

100-800 |

100-2000 |

1800X1800X2000 |

3.0 |

|

GS1000 |

1100-2000 |

800-1800 |

150-1000 |

100-3000 |

1950X2000X2100 |

4.0 |

|

GD200 |

200-600 |

150-300 |

10-200 |

5-100 |

1000X1000X1200 |

1.2 |

|

GD300 |

600-1200 |

300-800 |

50-300 |

10-500 |

1200X1200X1400 |

1.5 |

|

GD400 |

700-1400 |

300-1200 |

50-400 |

100-1000 |

1400X1400X1800 |

2.2 |

|

GD600 |

800-1600 |

400-1400 |

50-600 |

100-1500 |

1600X1600X1900 |

2.5 |

|

GD800 |

1000-1800 |

500-1500 |

10-800 |

100-2000 |

1800X1800X2000 |

3.0 |

|

GD1000 |

1100-2000 |

800-1800 |

150-1000 |

100-3000 |

1950X2000X2100 |

4.0 |

|

GW300 |

100-300 |

300-600 |

100-300 |

50-500 |

1500X1500X1700 |

1.5 |

|

GW600 |

200-300 |

400-600 |

100-400 |

100-1000 |

1700X1600X1800 |

2.3 |

|

GW1200 |

500-900 |

800-1200 |

300-500 |

100-1300 |

1800X1700X2000 |

2.5 |

|

GW1600 |

1000-1500 |

1000-1600 |

500-1000 |

100-1500 |

1900X2000X2100 |

3.0 |

More information:

6 TYPES COIL WRAPPING MACHINE BEST PRACTICES WITH COIL PACKAGE

MORE COIL WRAPPING MACHINES SOLUTION

Reference:

Coiled material automatic packaging apparatus

Shuttle change system and method for wrapping apparatus

Automation for steel industry packaging